2025 - APT Student Masonry Arch Competition

Project Details

Team: Tim Michiels (faculty advisor), Elizabeth Kostina (team captain), Matt Goff, Fikri Izza, Yuhan (Alex) Shi, Sabina Busch, Heather Oakley, Abbey Rae Francis, Ashlyn Pause, Gala Westbroek Cooper, Noah Bronowich

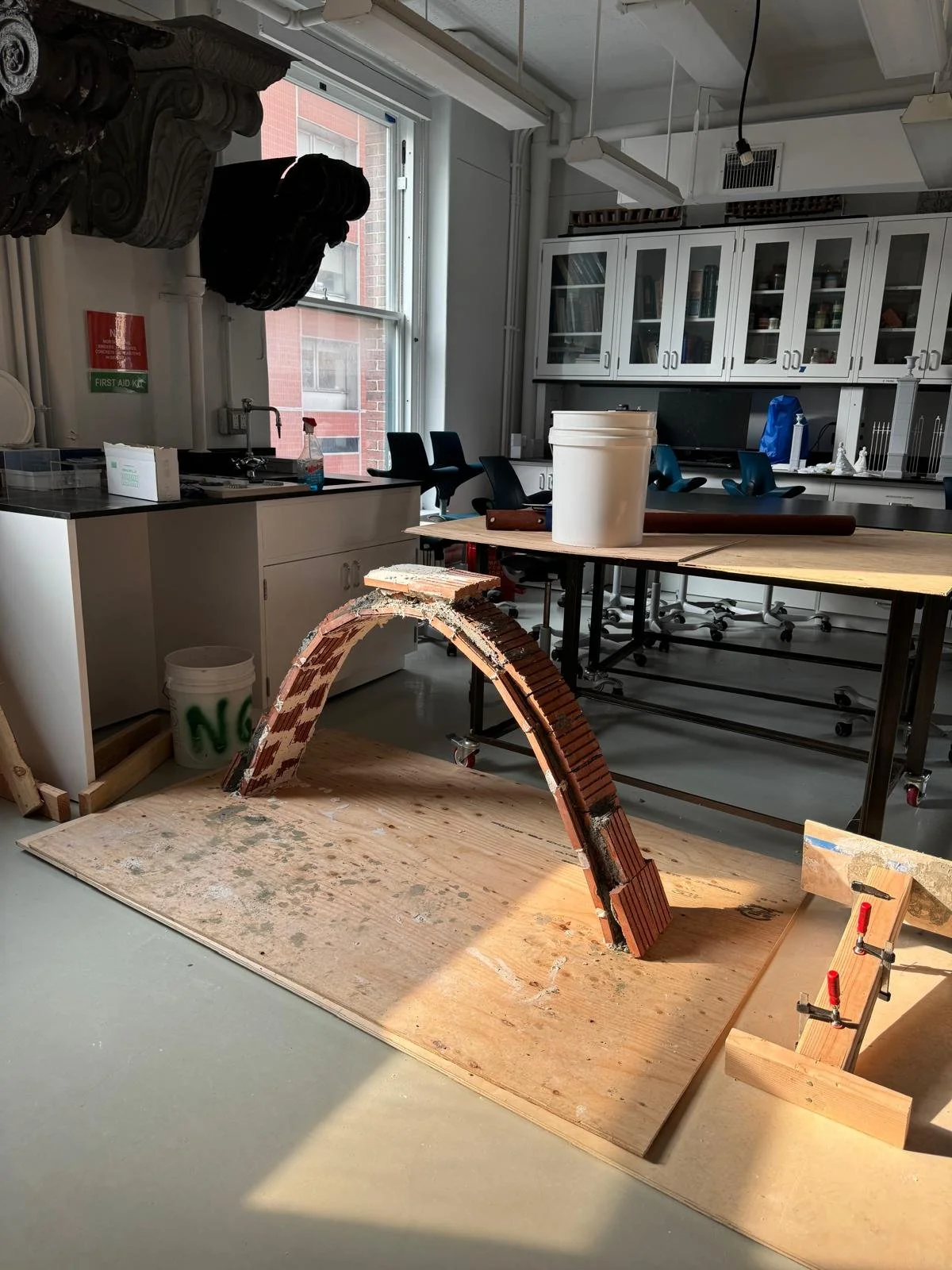

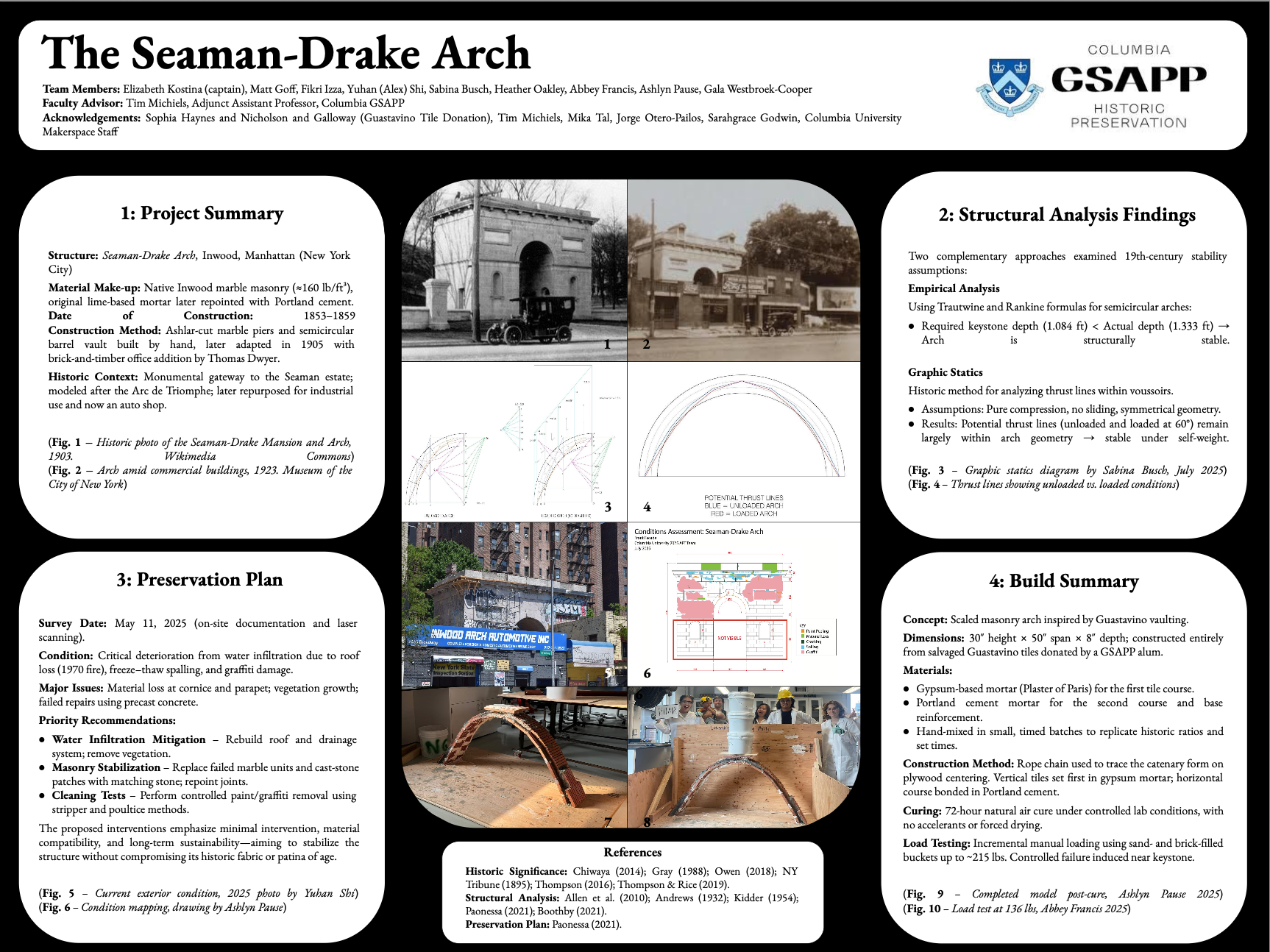

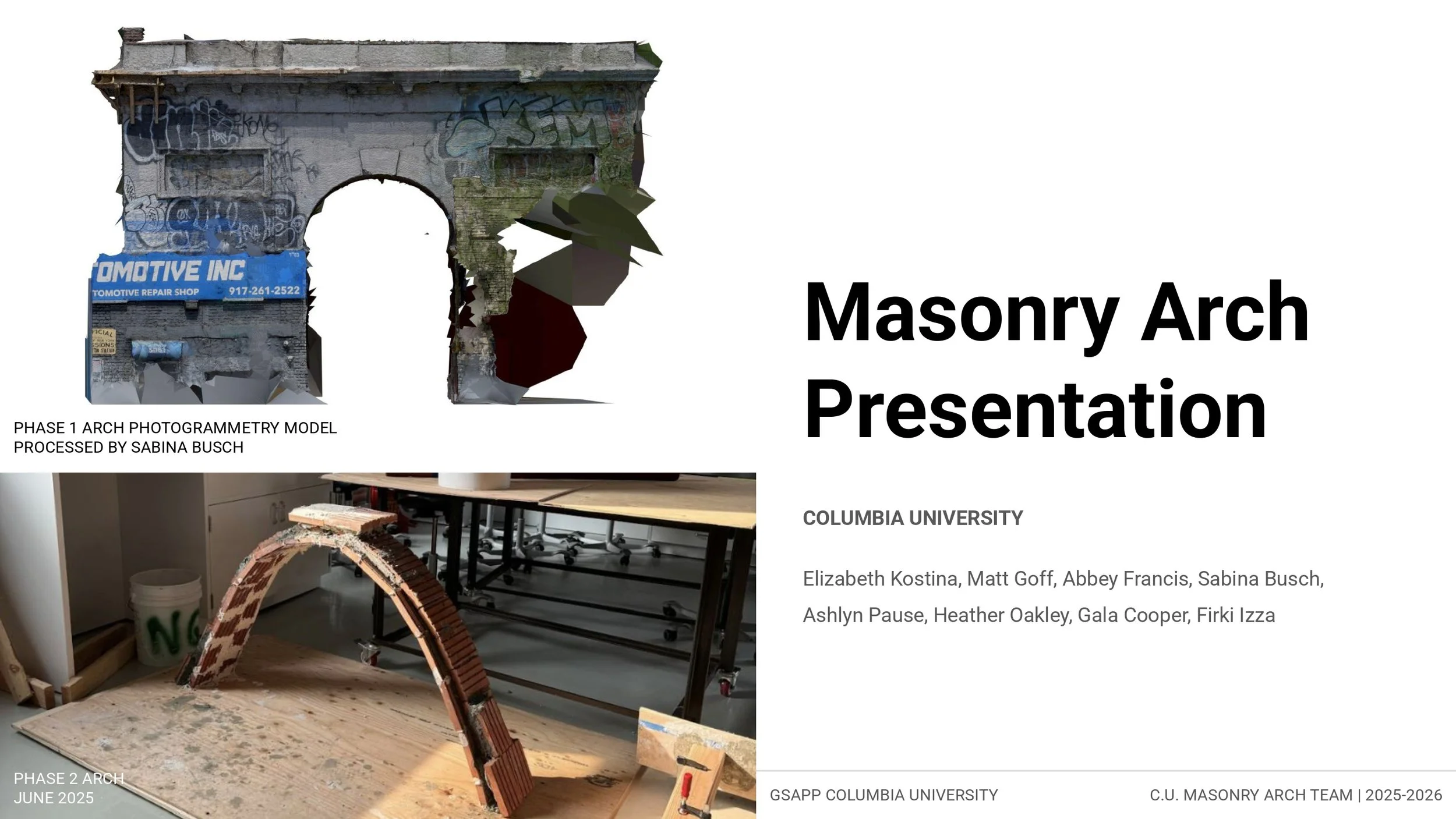

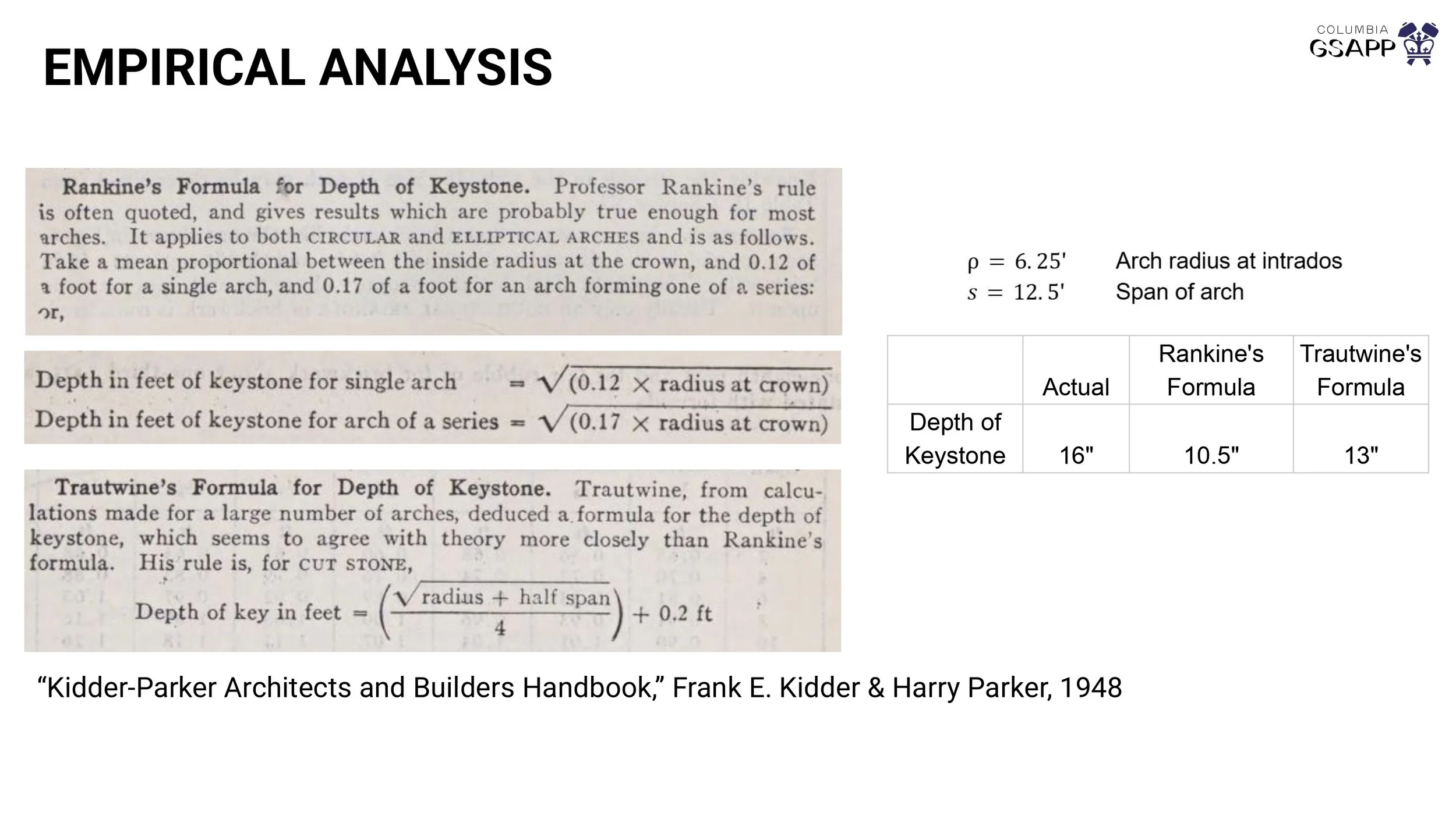

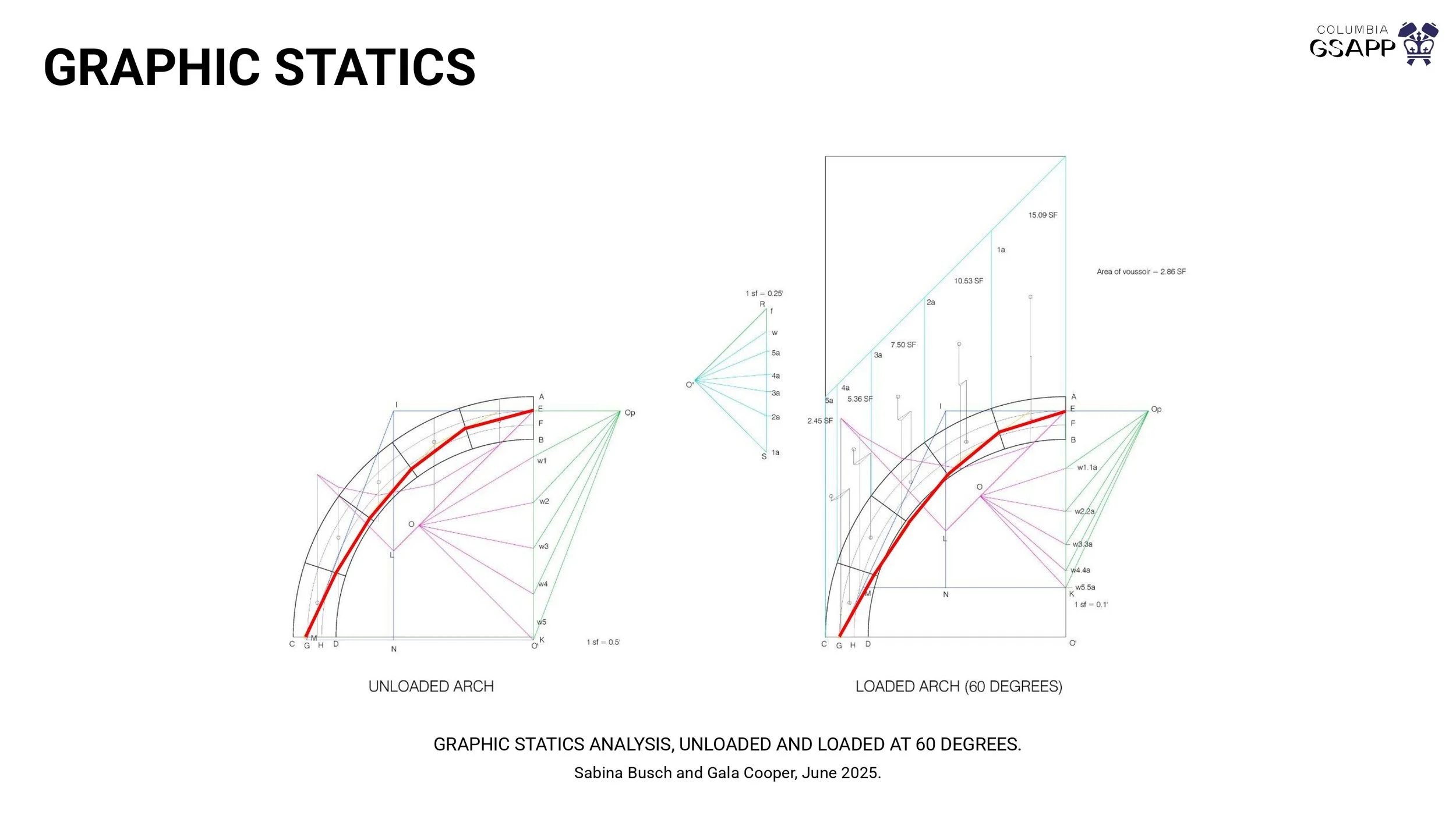

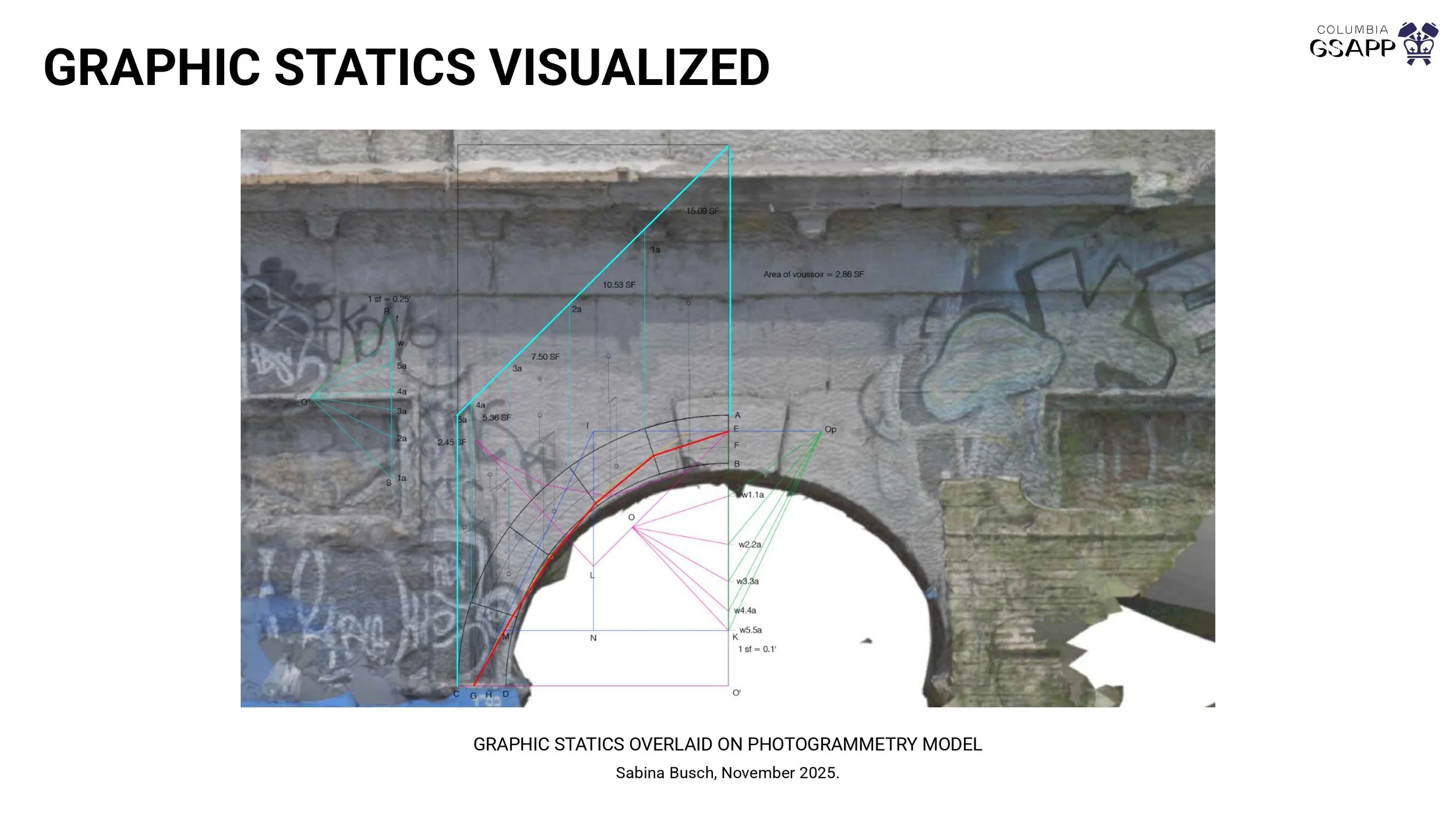

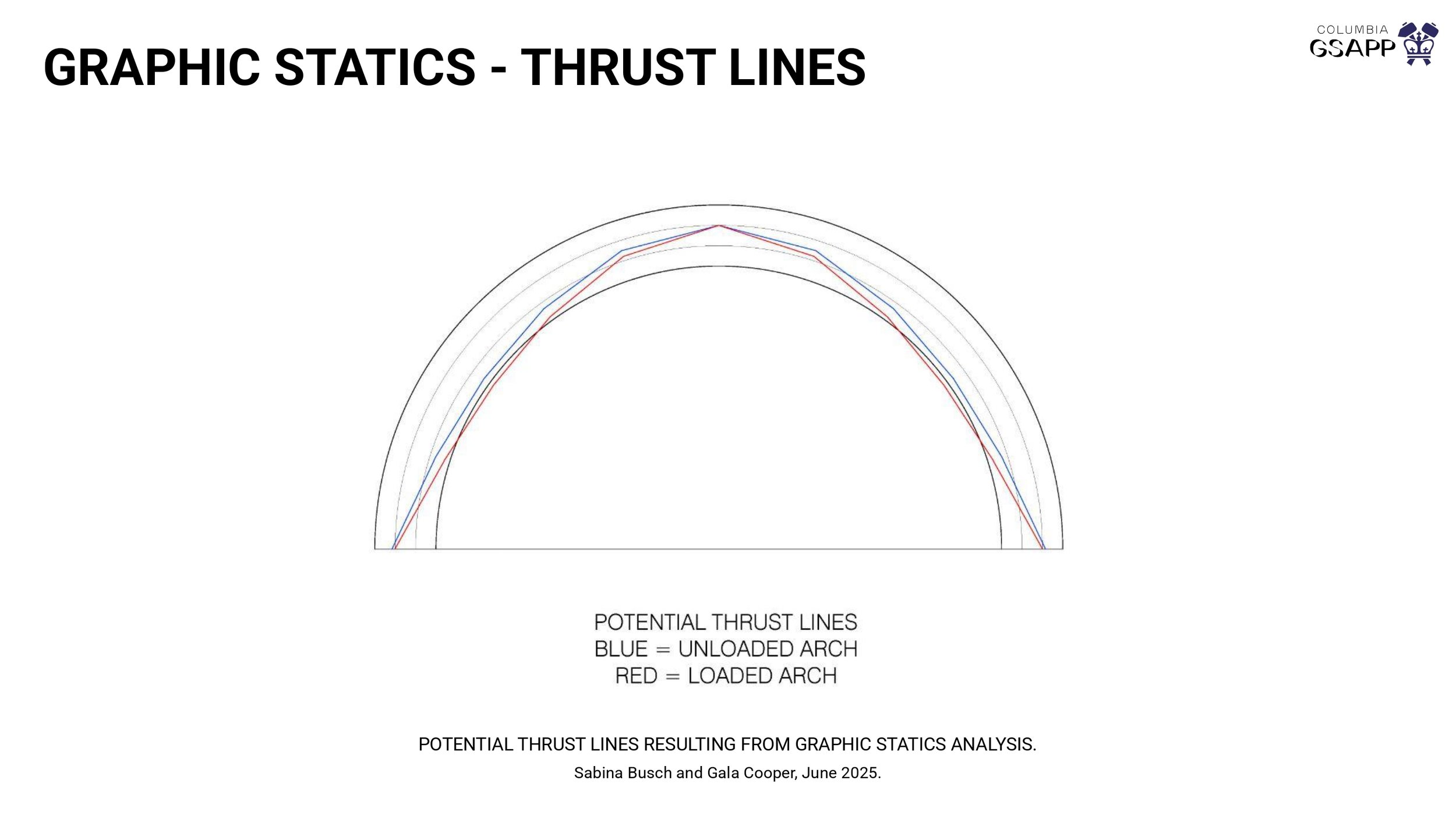

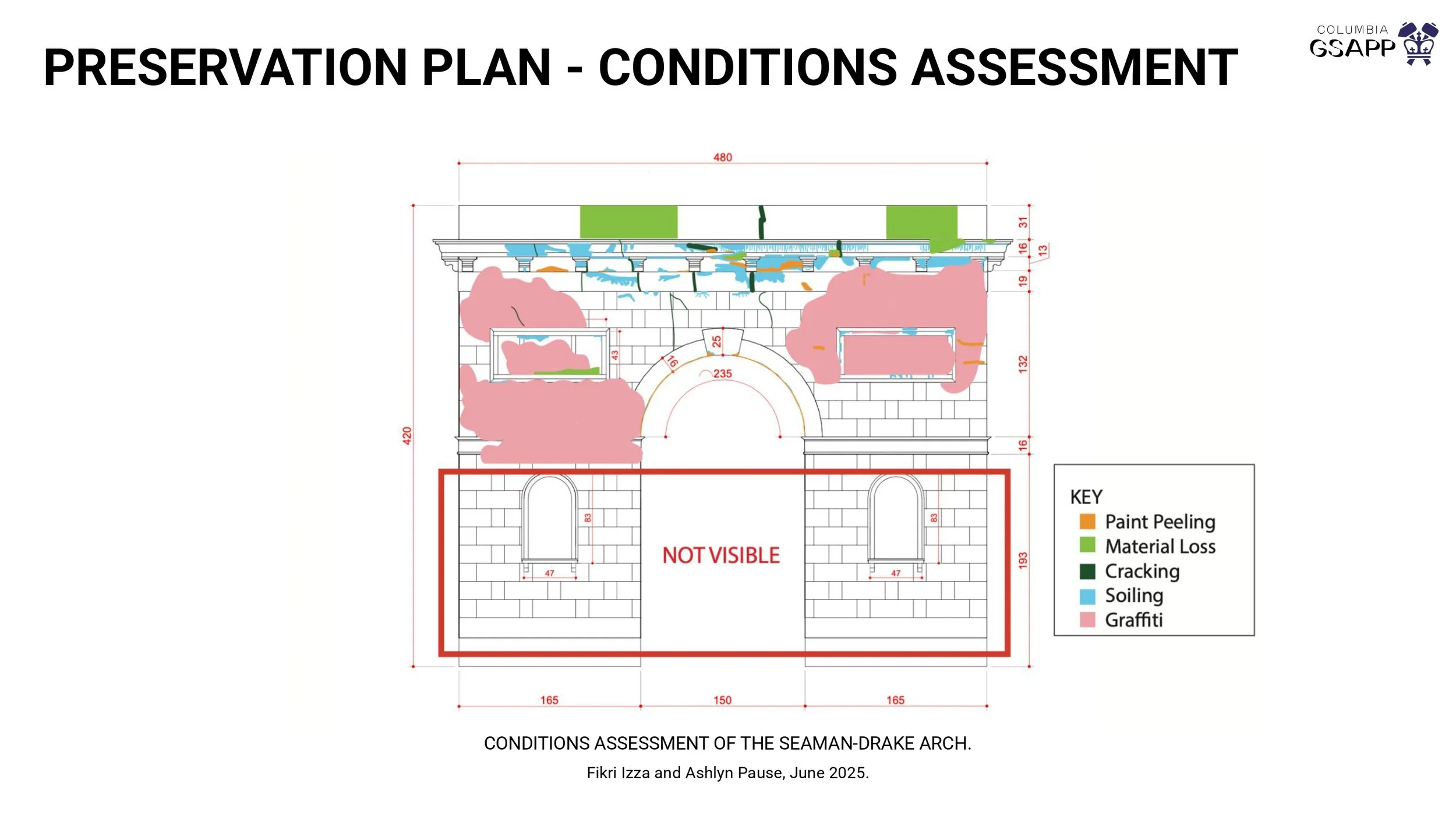

Phase 1 & 2 (Historic Research and On-Campus Build): conducted historical research and materials analysis/documentation of the condition of the Seaman-Drake Arch, 215th Street and Broadway, Inwood, Manhattan, New York. Documentation Methods included laser scanning, hand measurement, photographic documentation, archival research, condition assessment, graphic statics analysis, and empirical structural calculations (Trautwine's Formula, Rankine's Formula, graphic statics (following Kidder 1954 methodology), funicular polygon construction, thrust line analysis). Phase 2 arch construction was completed using Salvaged Guastavino tiles (3" × 5"), gypsum-based mortar (Plaster of Paris), Portland cement mortar, plywood formwork

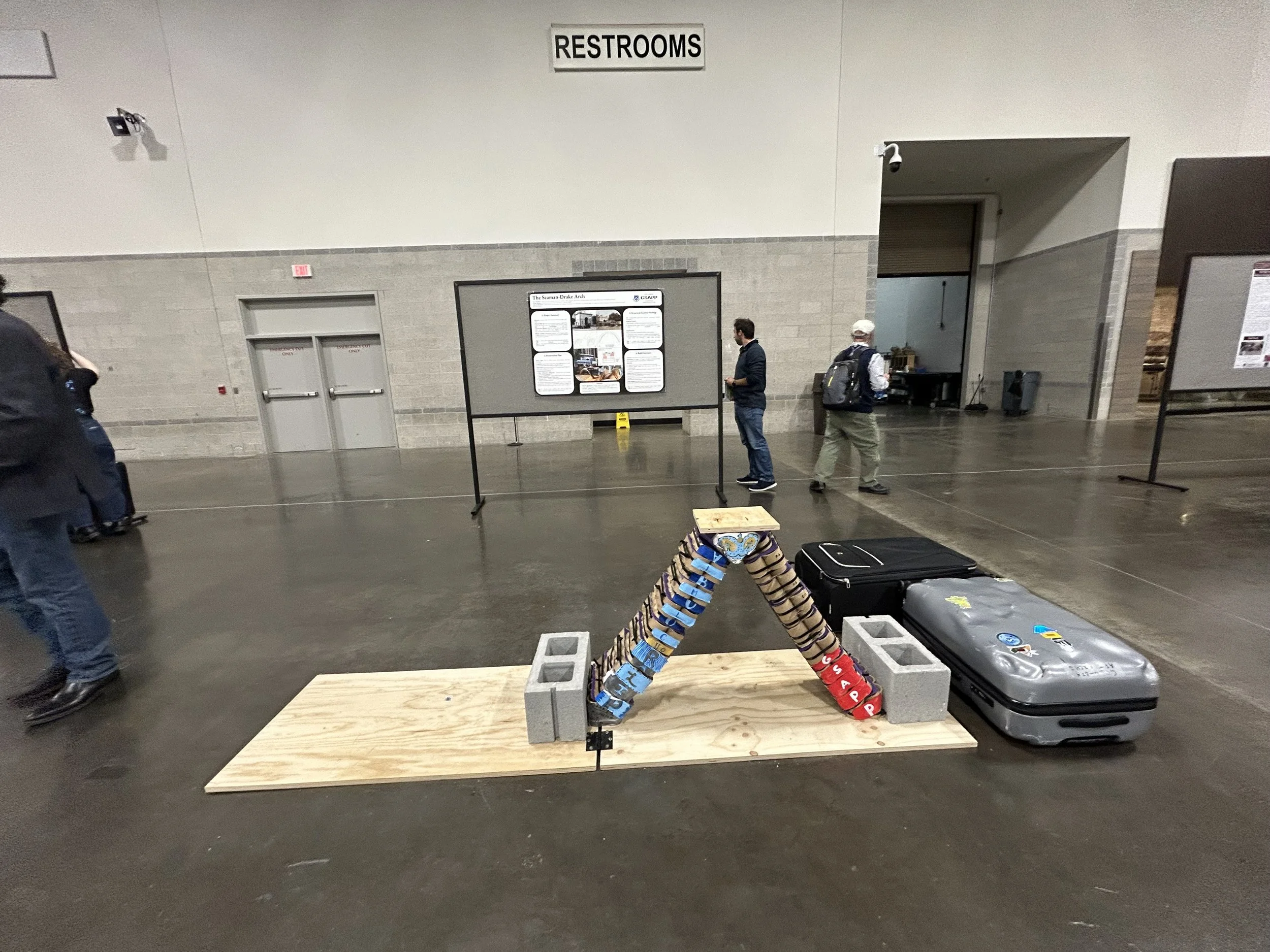

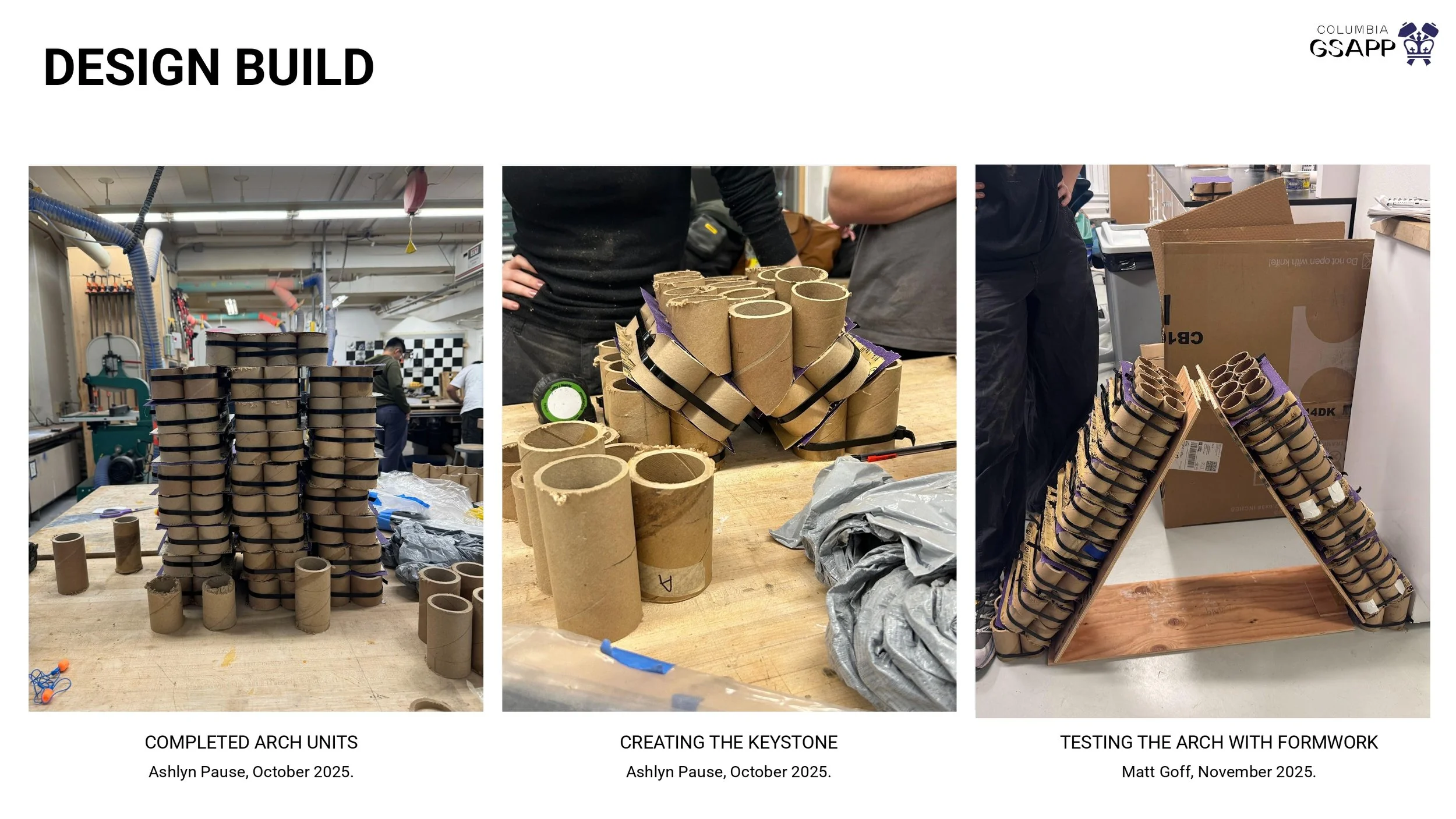

Phase 3 (Conference Competition): Held at the APT Annual Conference, Providence, Rhode Island (November 11-15, 2025), the student competition invited students to build a dry stack arch in as little time as possible that would hold as much weight as possible, taking what had been learned during phase 2. The Columbia team used carpet tubes bundled in 8-tube composite elements to complete the build of a dry-stack compression-only structure with no mortar, adhesives, or mechanical fasteners.

Competition Phase 1: Historic Research

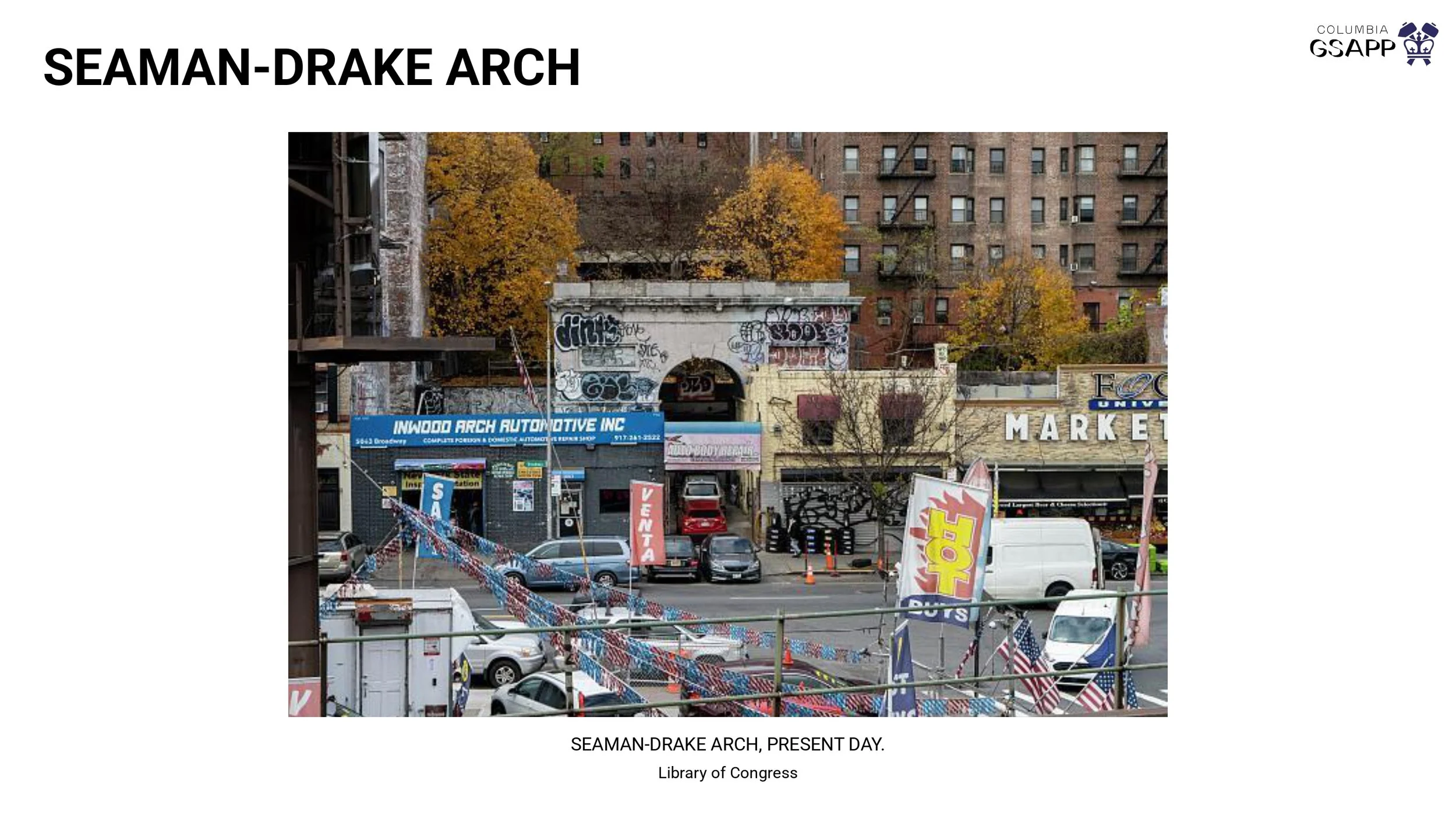

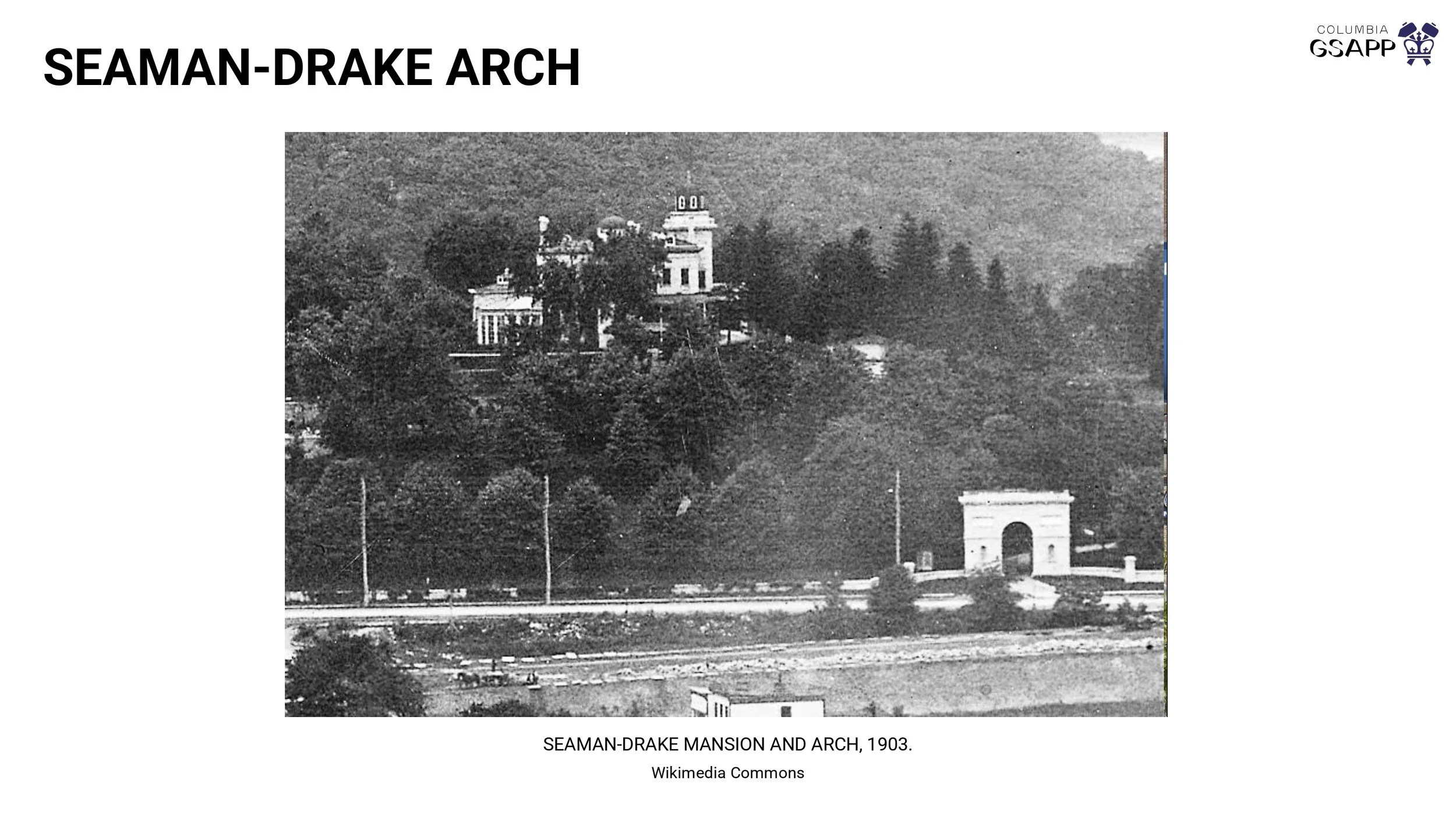

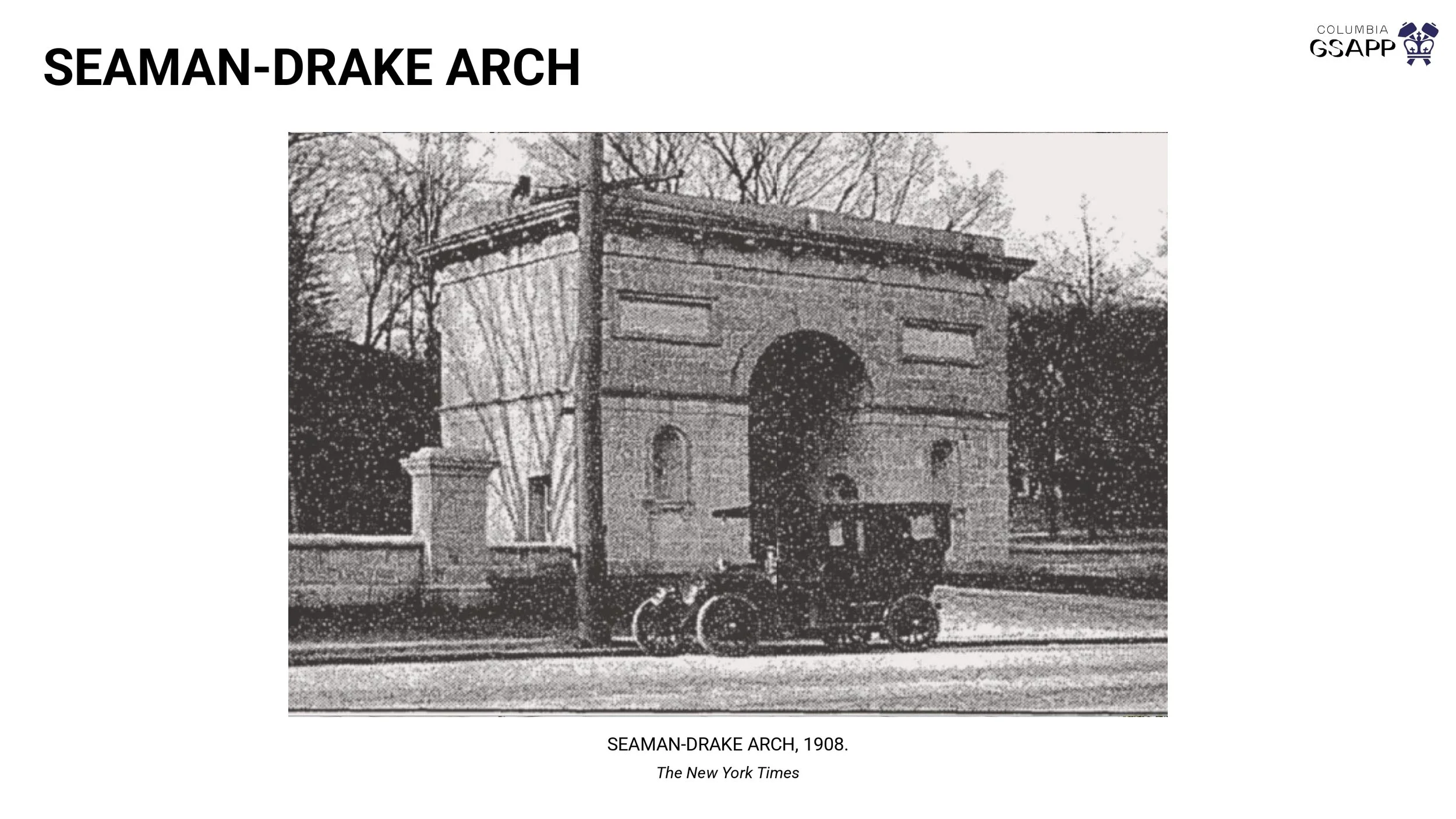

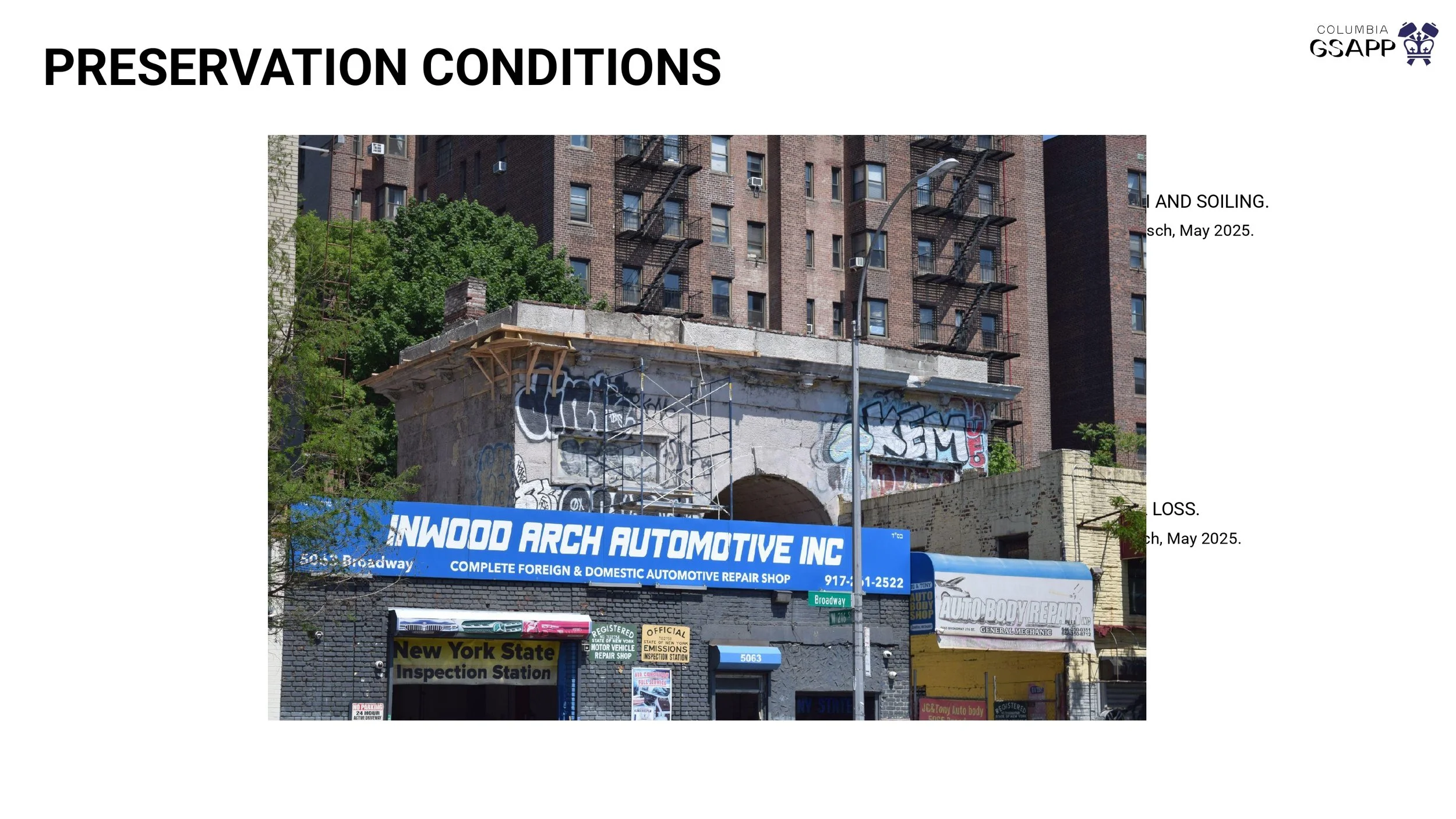

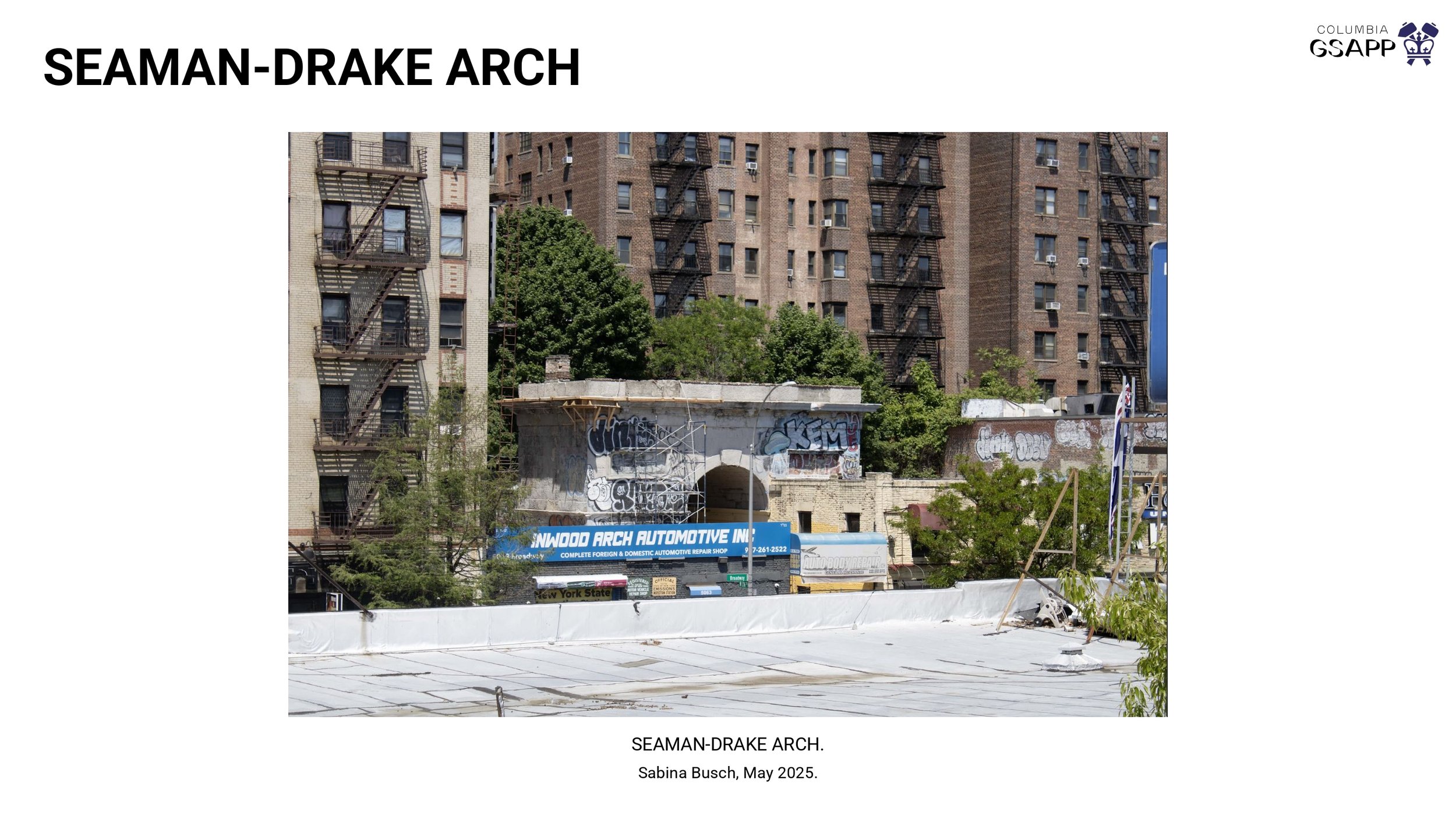

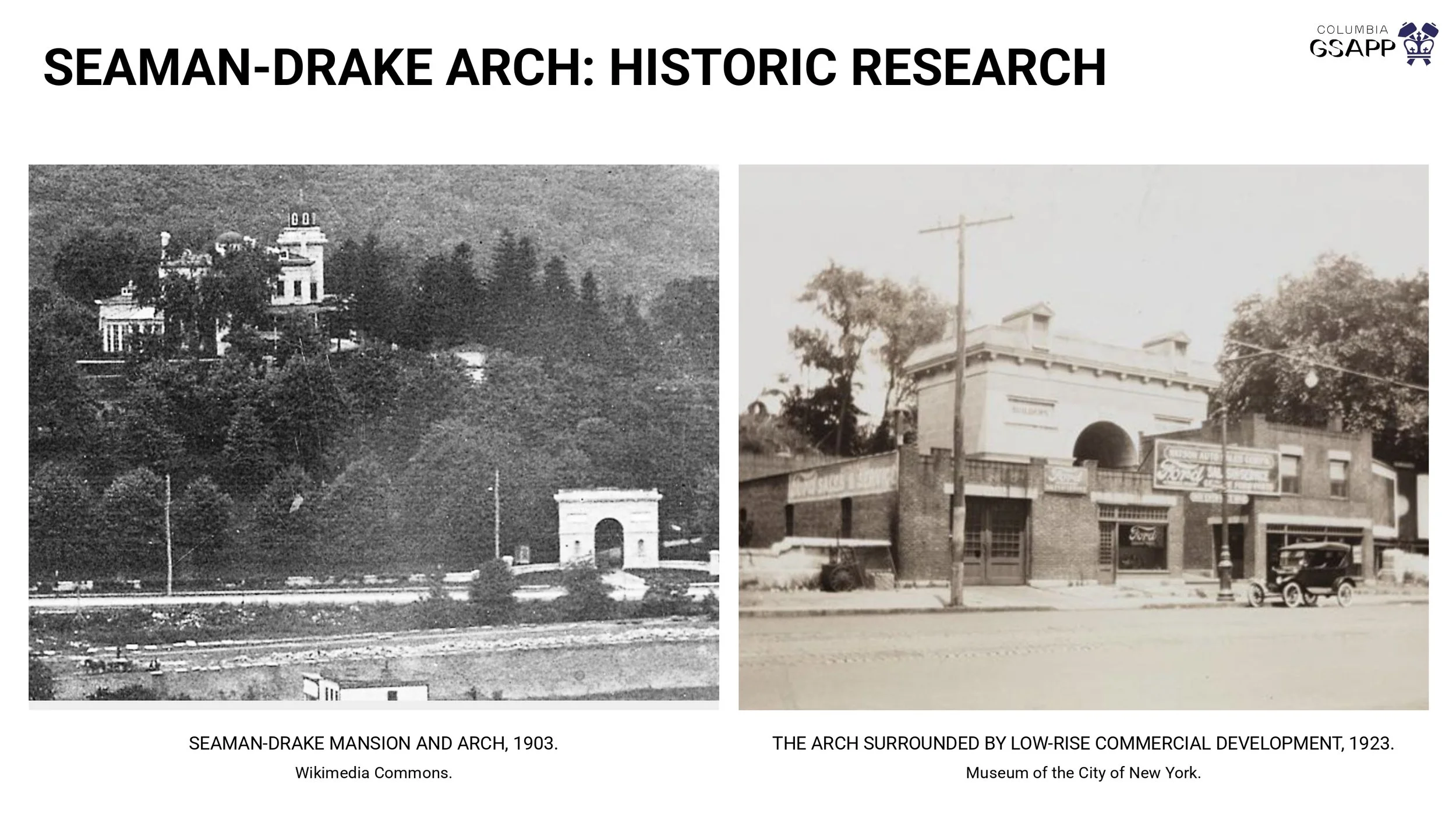

Columbia University's Historic Preservation team participated in the 2025 Association for Preservation Technology (APT) Student Design-Build Competition, selecting the Seaman-Drake Arch in Inwood, Manhattan as our case study. This remarkable structure, built 1853-1859 from native Inwood marble, once served as the monumental gateway to a vast private estate but now stands deteriorating among auto repair shops, a forgotten relic of New York history.

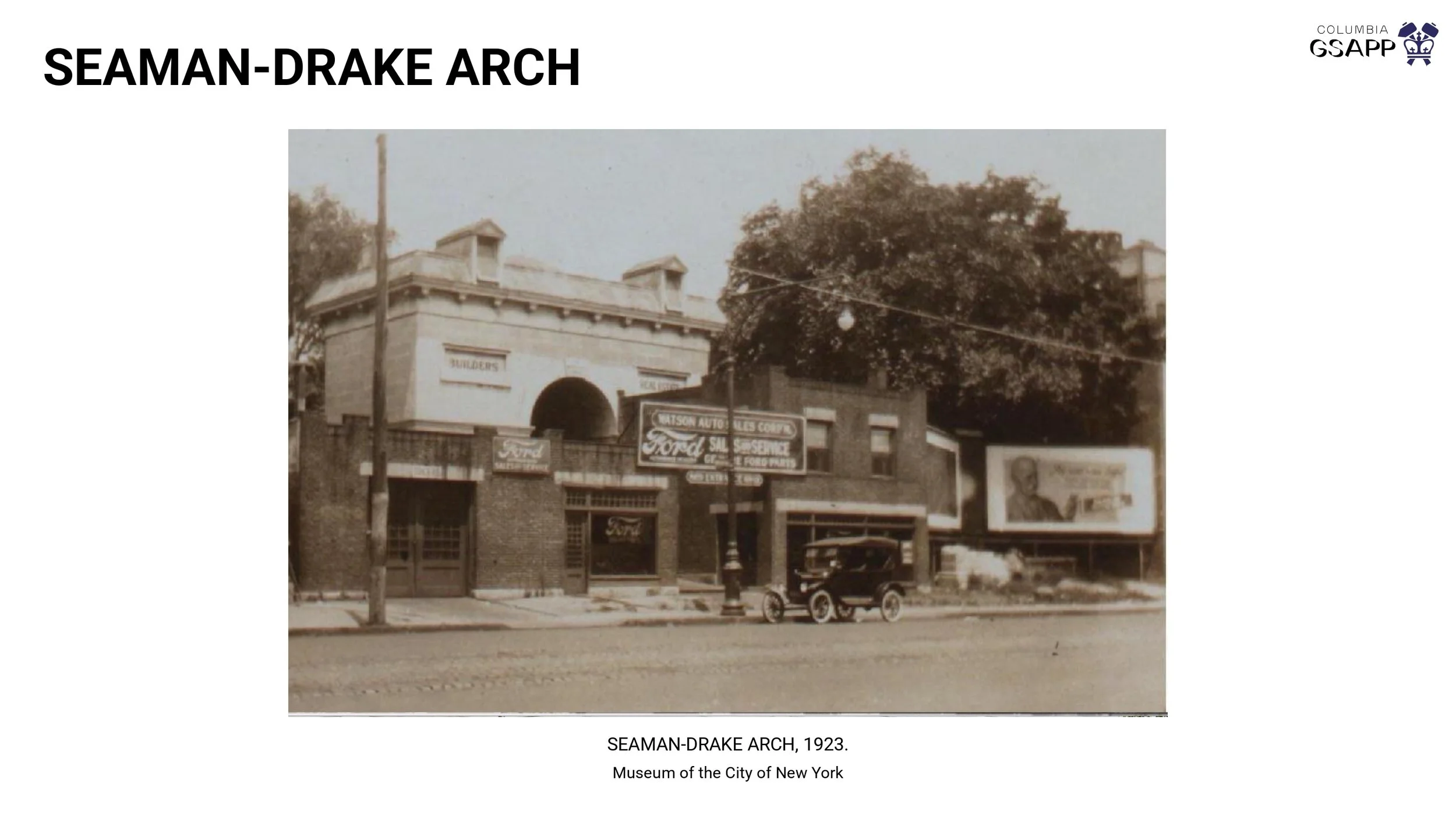

The team traced the arch's transformation from a $40,000 "Mt. Olympus" estate entrance (nicknamed "Seaman's Folly" by critics) through its 20th-century adaptation as commercial headquarters for the Marble Arch Company, to its current precarious state as an auto shop facade. Research revealed both the structure's architectural significance and its material vulnerability; the porous Inwood marble that once made construction economical has proven catastrophically unsuited to Manhattan's freeze-thaw cycles.

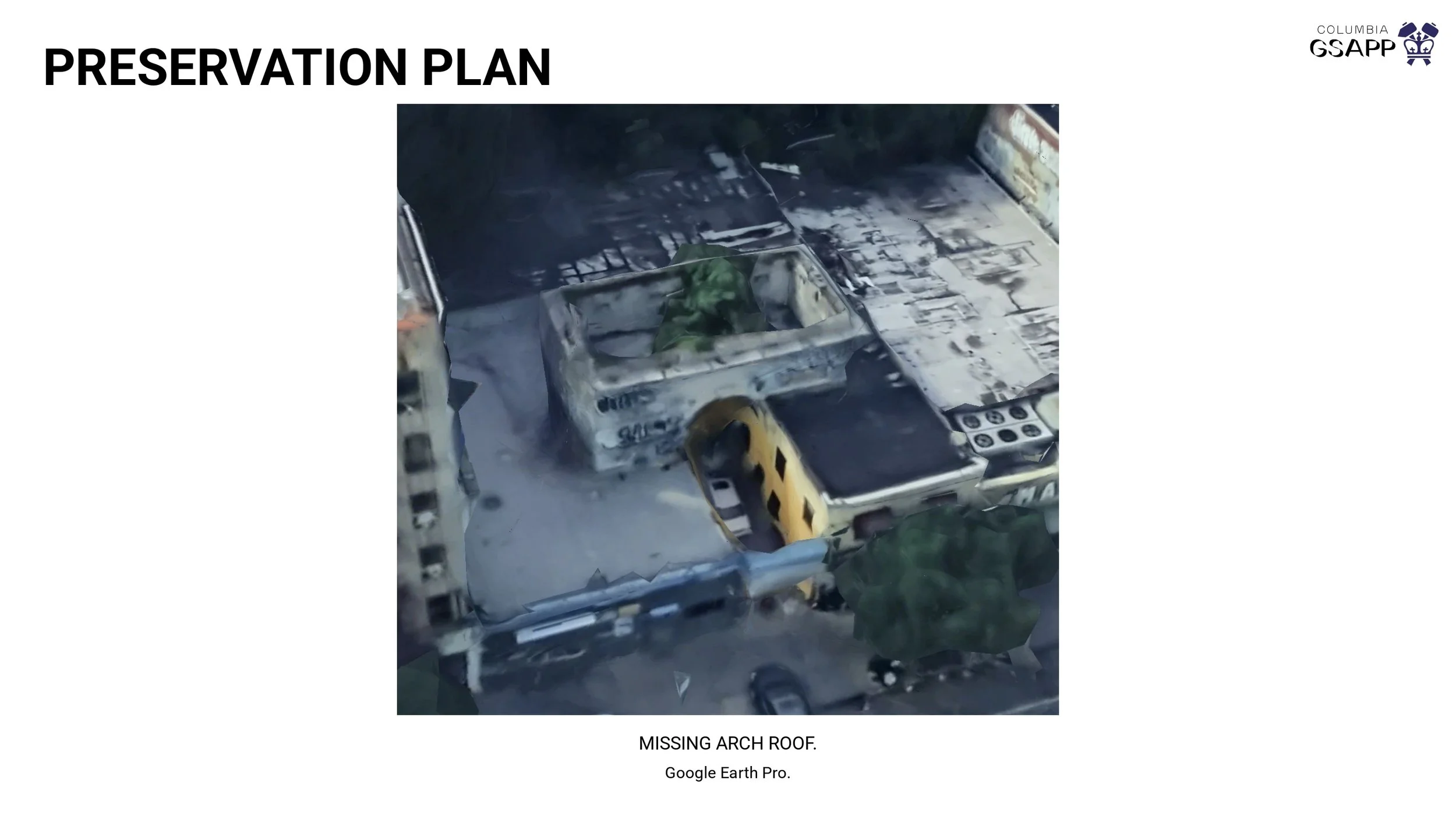

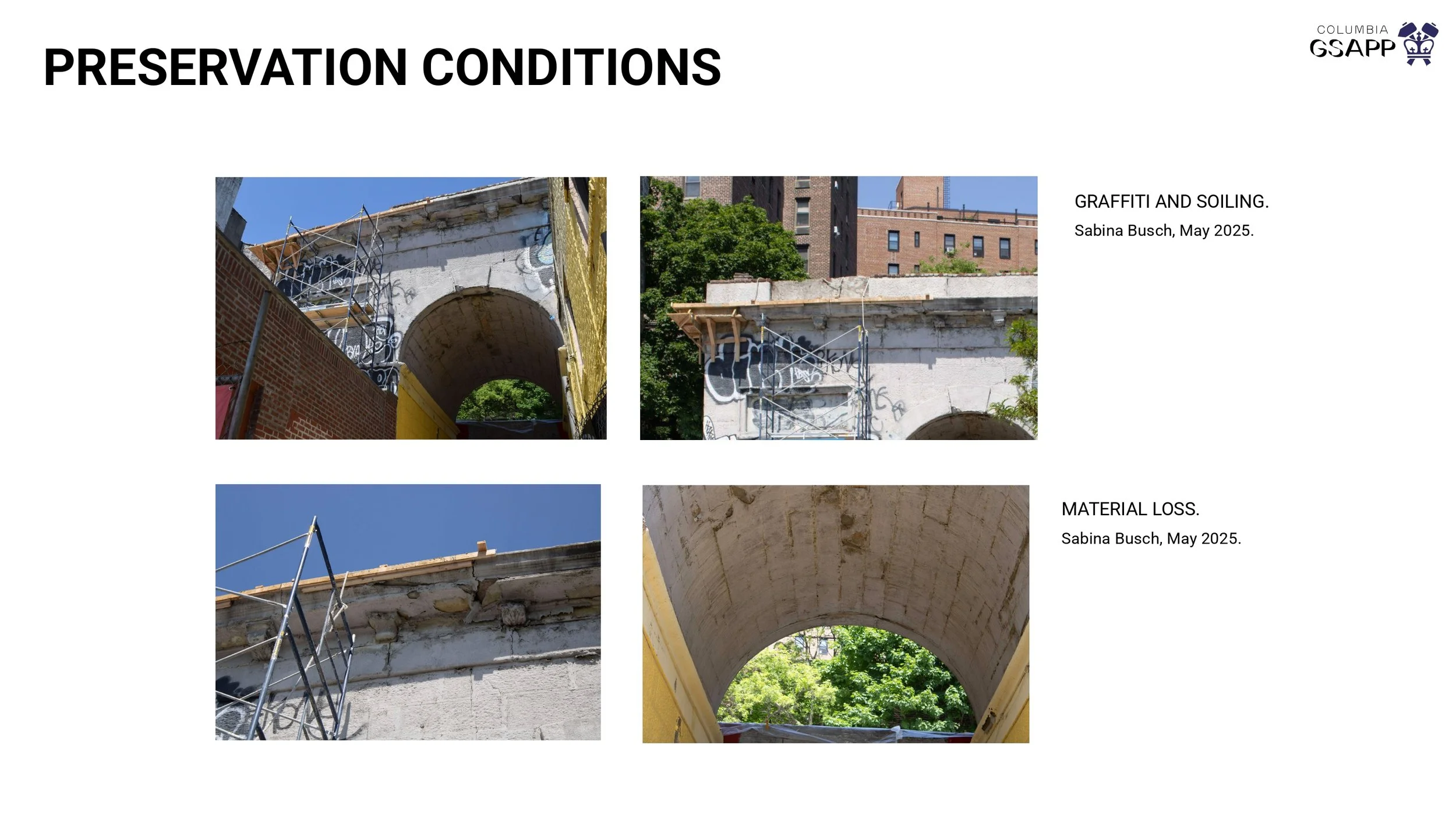

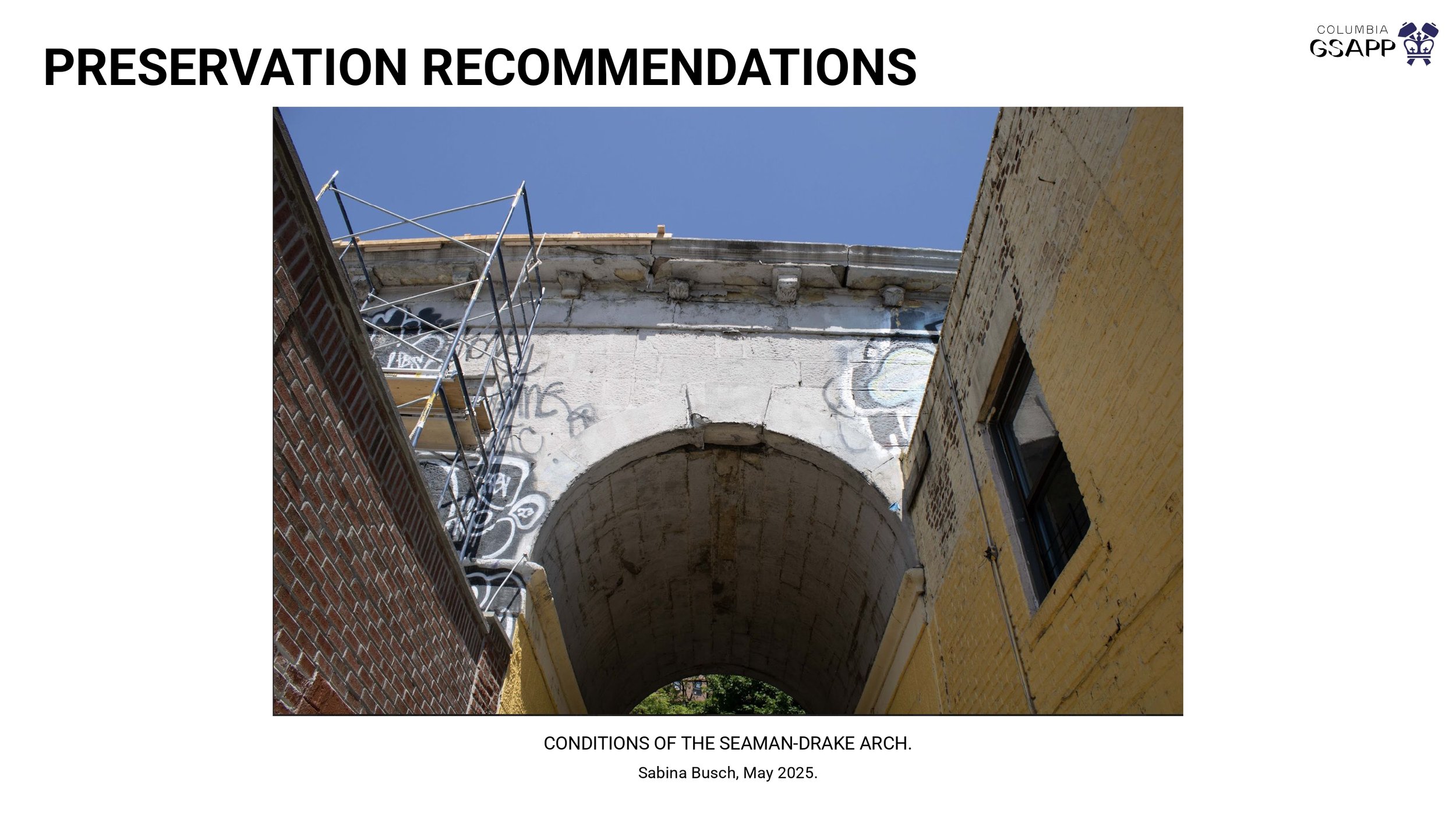

Using historic engineering methods, the team analyzed the semicircular arch through both empirical formulas (Trautwine and Rankine) and graphic statics techniques from 1954 engineering handbooks. By drawing funicular polygons and locating potential thrust lines through the masonry, they confirmed the arch remains structurally stable under self-weight despite extensive deterioration. Field documentation revealed critical conditions: extensive material loss at the cornice (temporarily supported by wooden scaffolding), failed repairs using inappropriate concrete replacements, heavy paint and graffiti accumulation, and dangerous spalling beneath the arch opening (currently "protected" by a debris-catching dumpster). The primary culprit: complete loss of the roof system in a 1970s fire, leaving the structure exposed to decades of water infiltration.

Competition Phase 2: Design-Build Execution

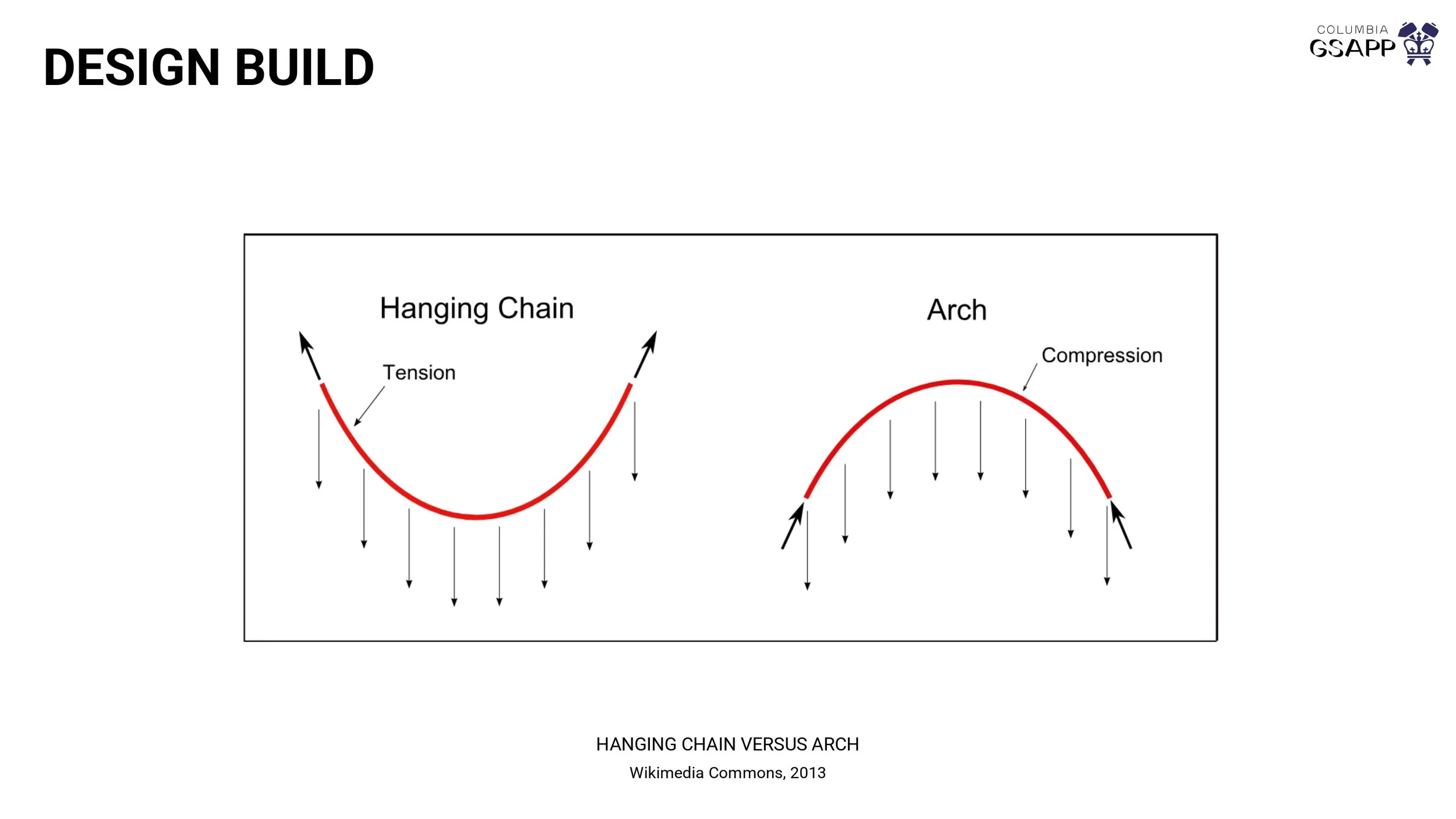

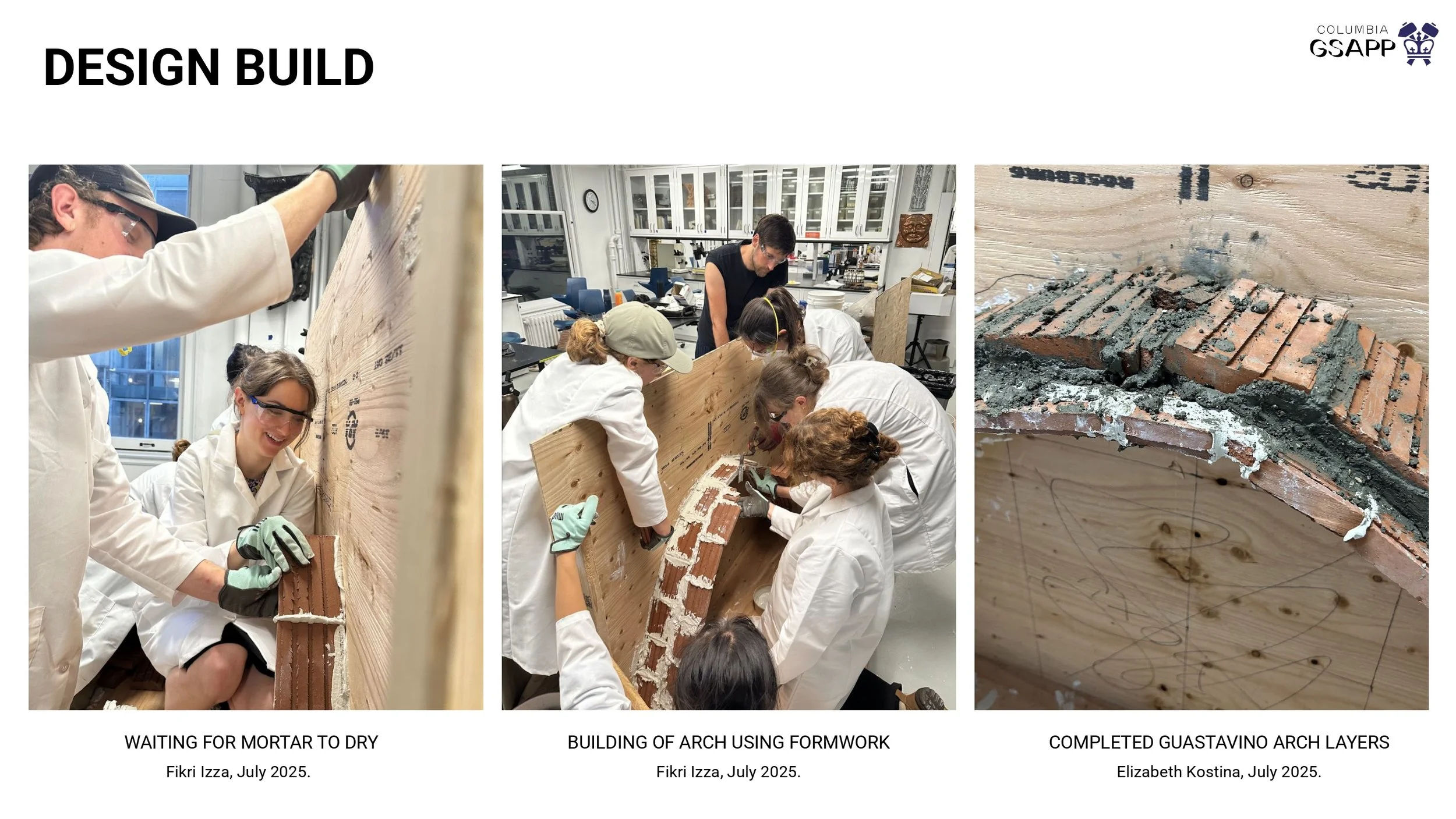

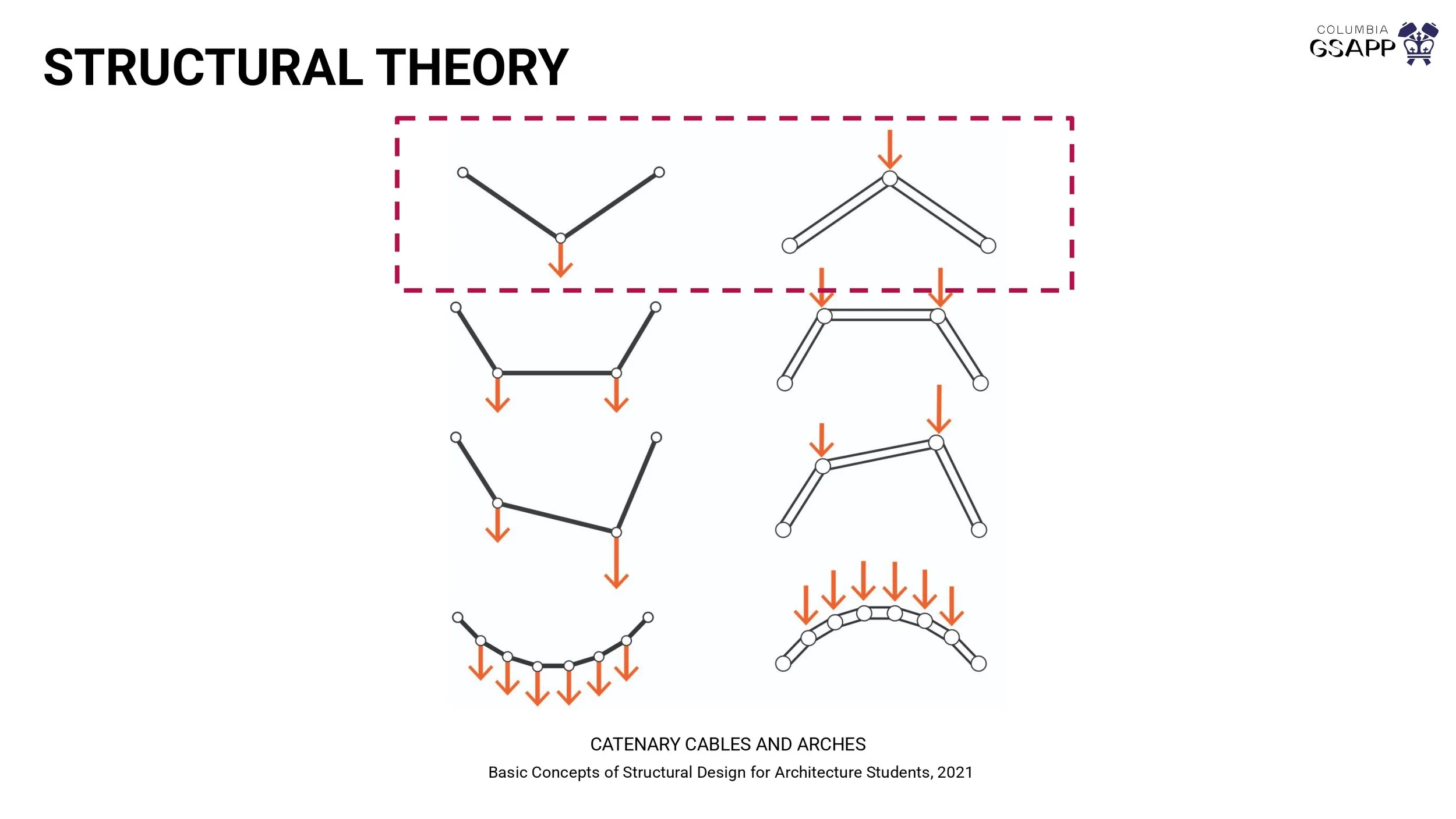

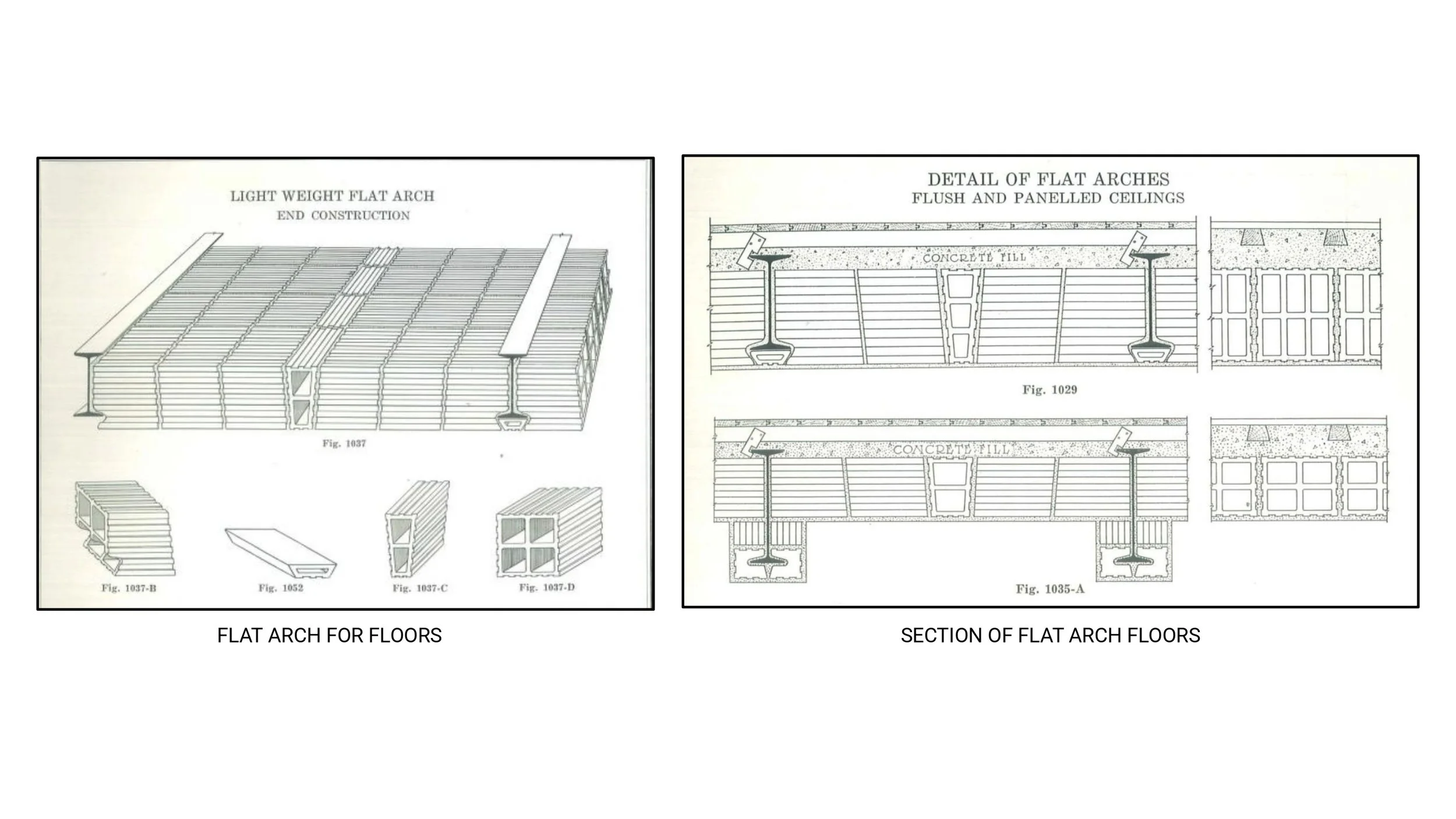

The team constructed a scaled arch inspired by Guastavino vaulting techniques, using salvaged authentic Guastavino tiles donated by a GSAPP alumnus. They determined the arch's catenary curve using a physical hanging chain model, the inverted form representing pure compression forces. Construction employed historic materials: gypsum-based mortar (Plaster of Paris) with minimal Portland cement, mixed in small batches due to rapid setting times. The two-layer system placed vertical tiles against formwork with gypsum mortar, then added horizontal tiles in a staggered pattern with Portland cement mortar, creating the characteristic overlapping bond of thin-tile vaulting. After 72 hours of ambient curing, the formwork was removed, and the arch stood independently, achieving immediate stability through its optimized catenary geometry.

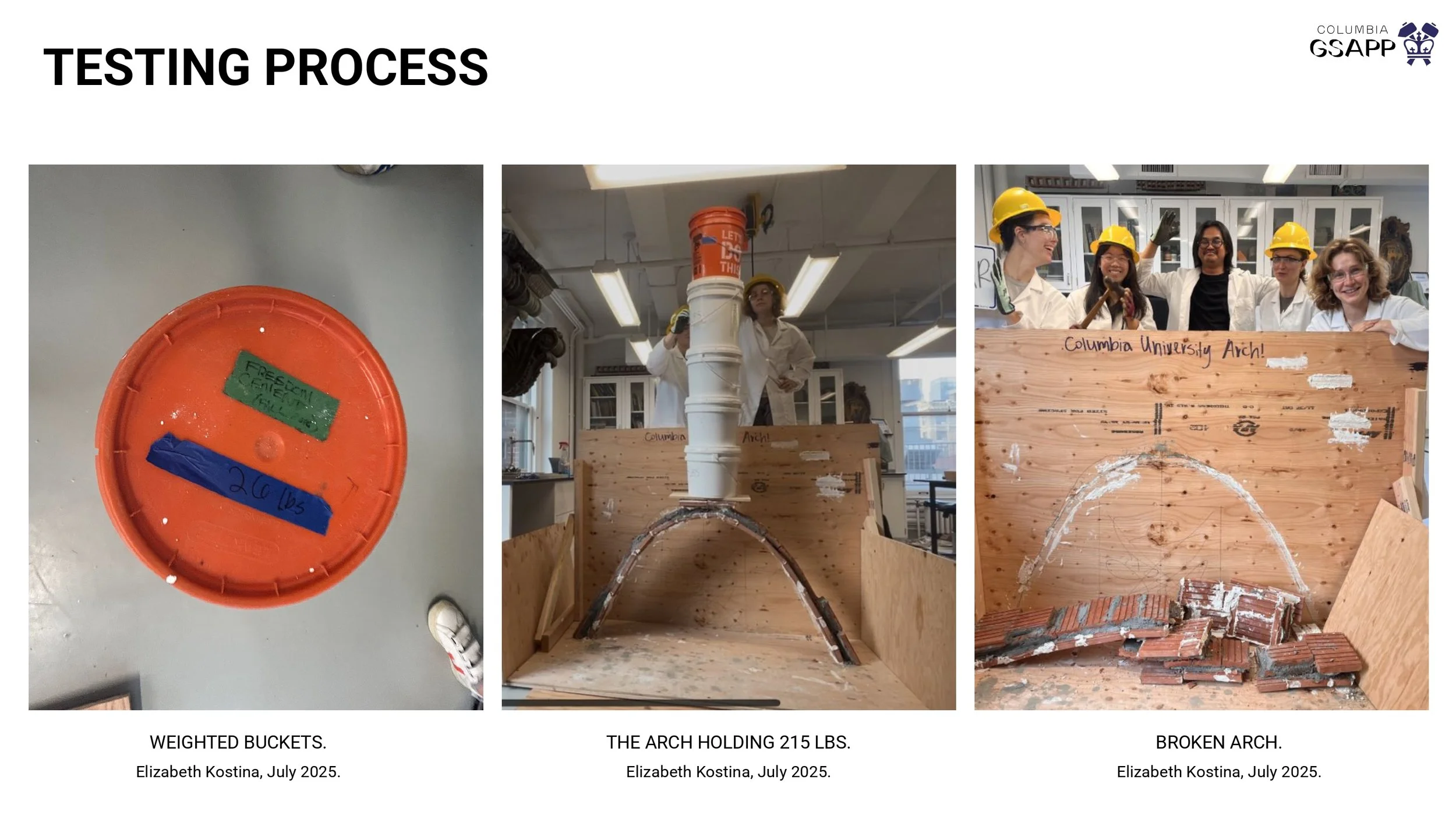

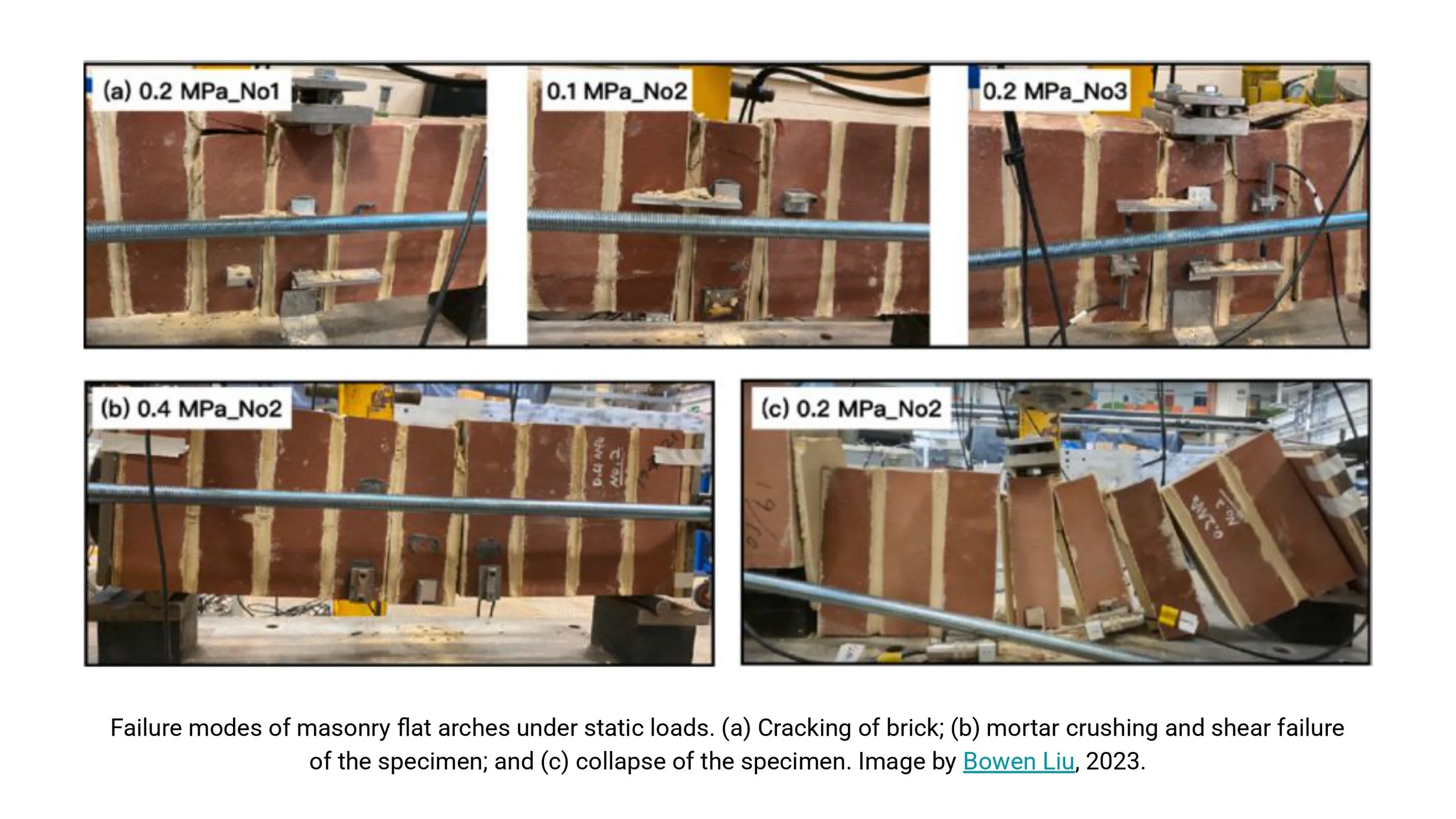

When the planned hydraulic load cell proved incompatible, the team pivoted to manual incremental loading using 5-gallon buckets filled with bricks and sand, carefully placed atop a centered plywood platform. The arch sustained 215 lbs (the maximum height constraints allowed) without any visible cracking, deflection, or displacement demonstrating the exceptional structural efficiency of catenary profiles and Guastavino-style construction. Final failure was induced by striking just right of the keystone, producing the anticipated 4-hinge collapse mechanism. The arch fractured into five distinct segments, confirming its reliance on continuous compressive forces and validating both the design methodology and the structural analysis predictions.

Competition Phase 3: Dry Stack Arch Build

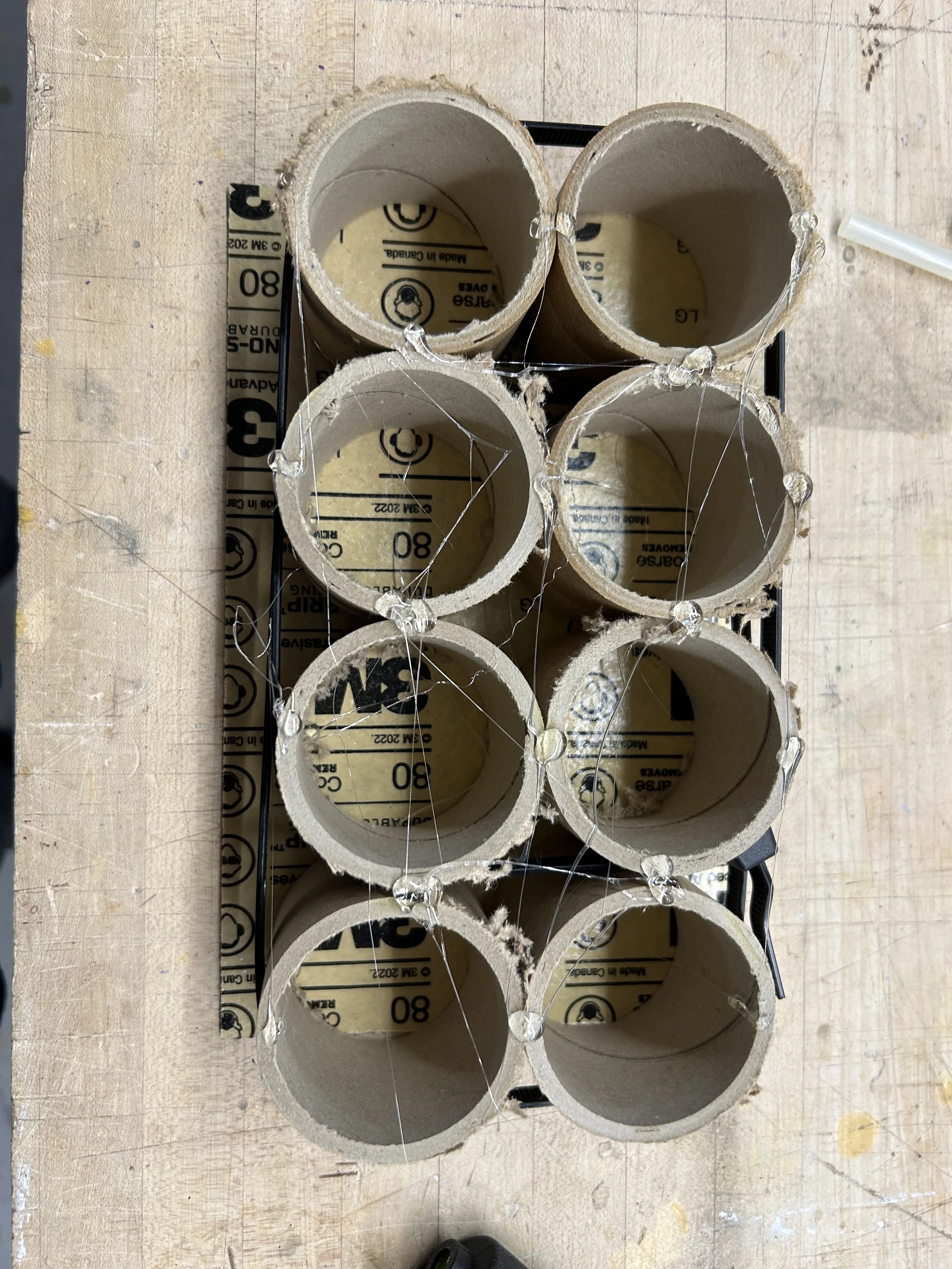

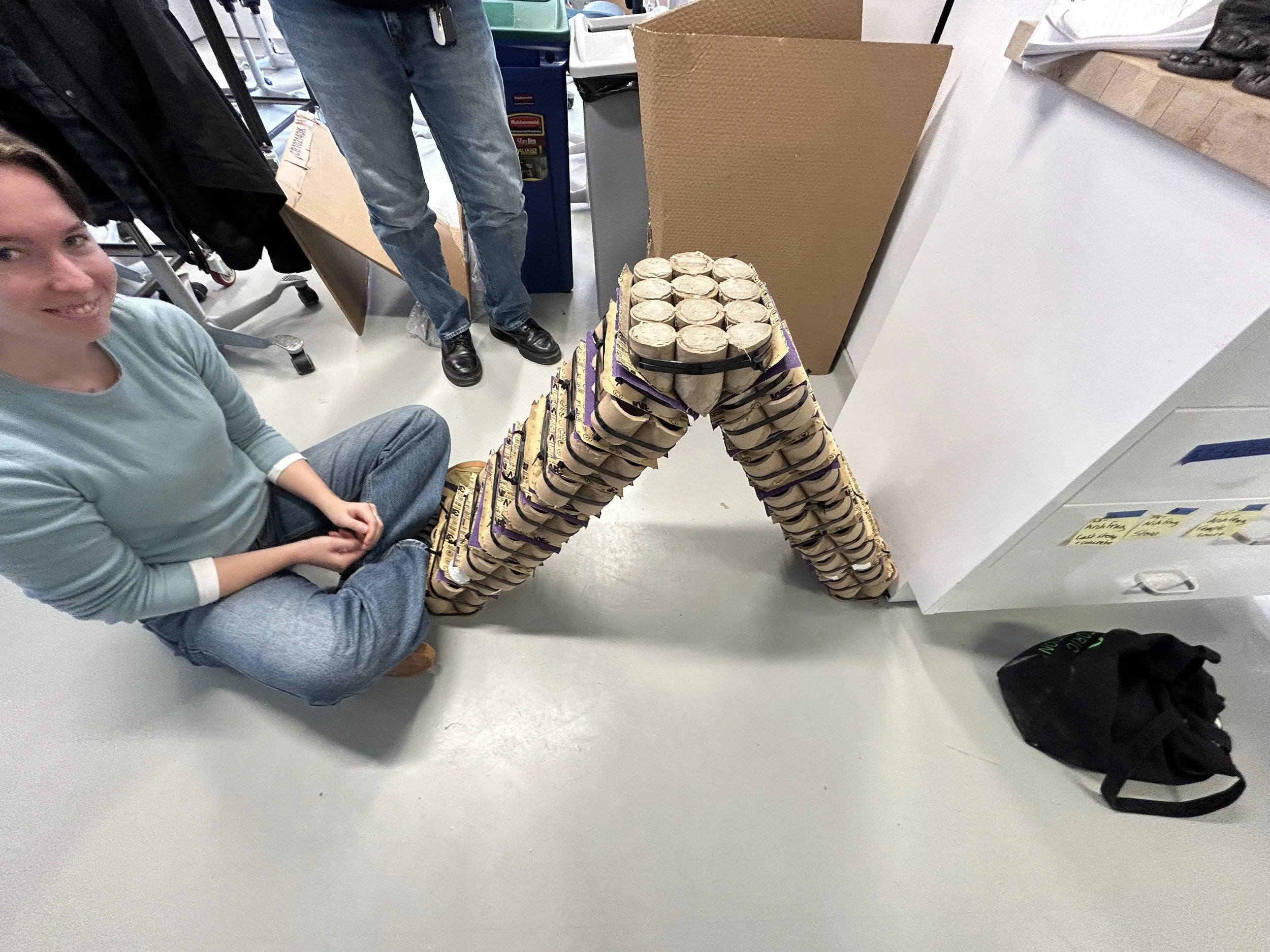

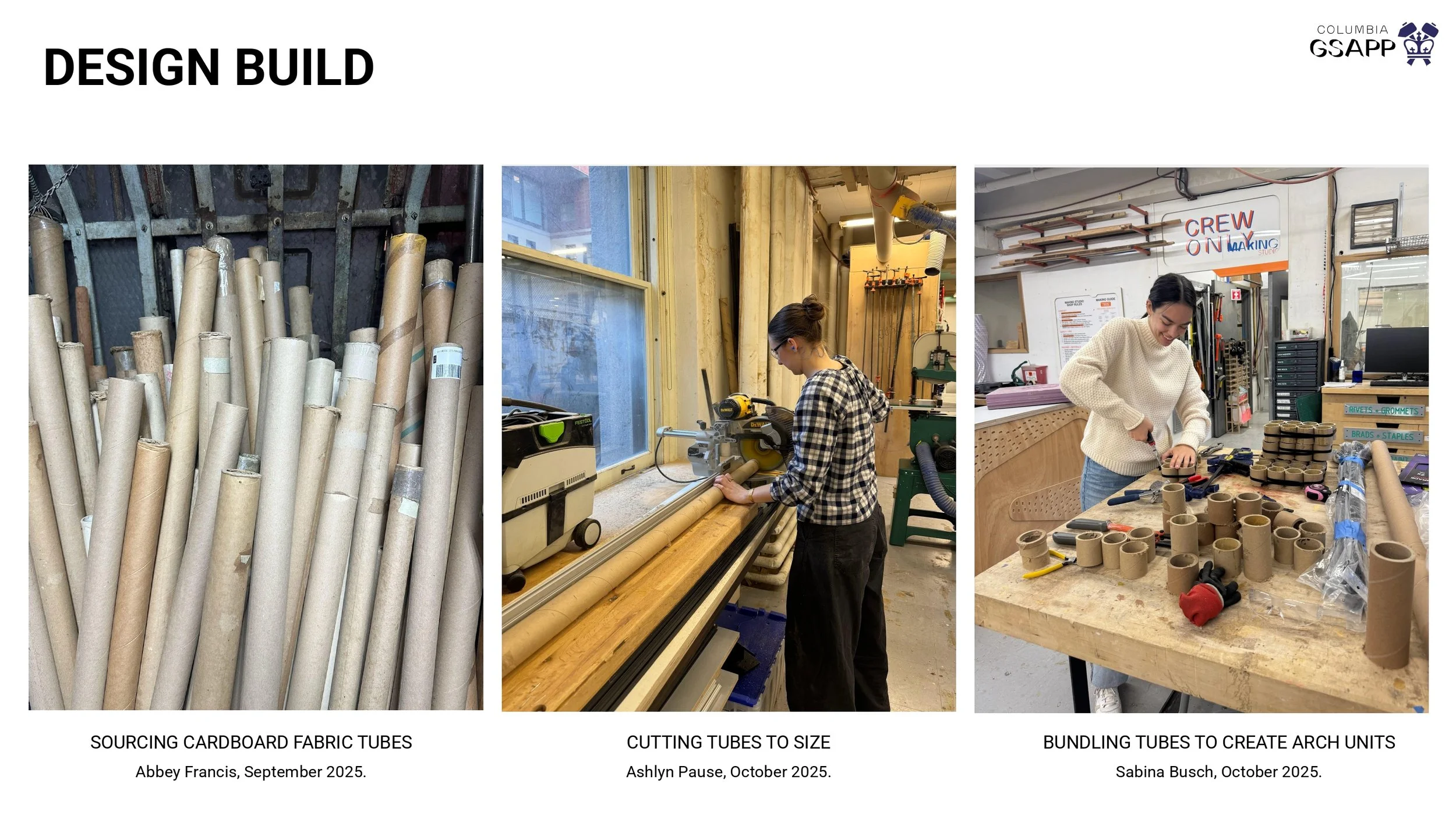

For the finals in Providence, Rhode Island, the team designed and fabricated a lightweight dry-stack arch optimized for transportation and rapid assembly. The design used recycled carpet cardboard tubes, an accessible, sustainable material that could be precisely cut and bundled to meet the competition's strict weight and volume constraints (four airline-checkable cases, maximum 50 lbs each).

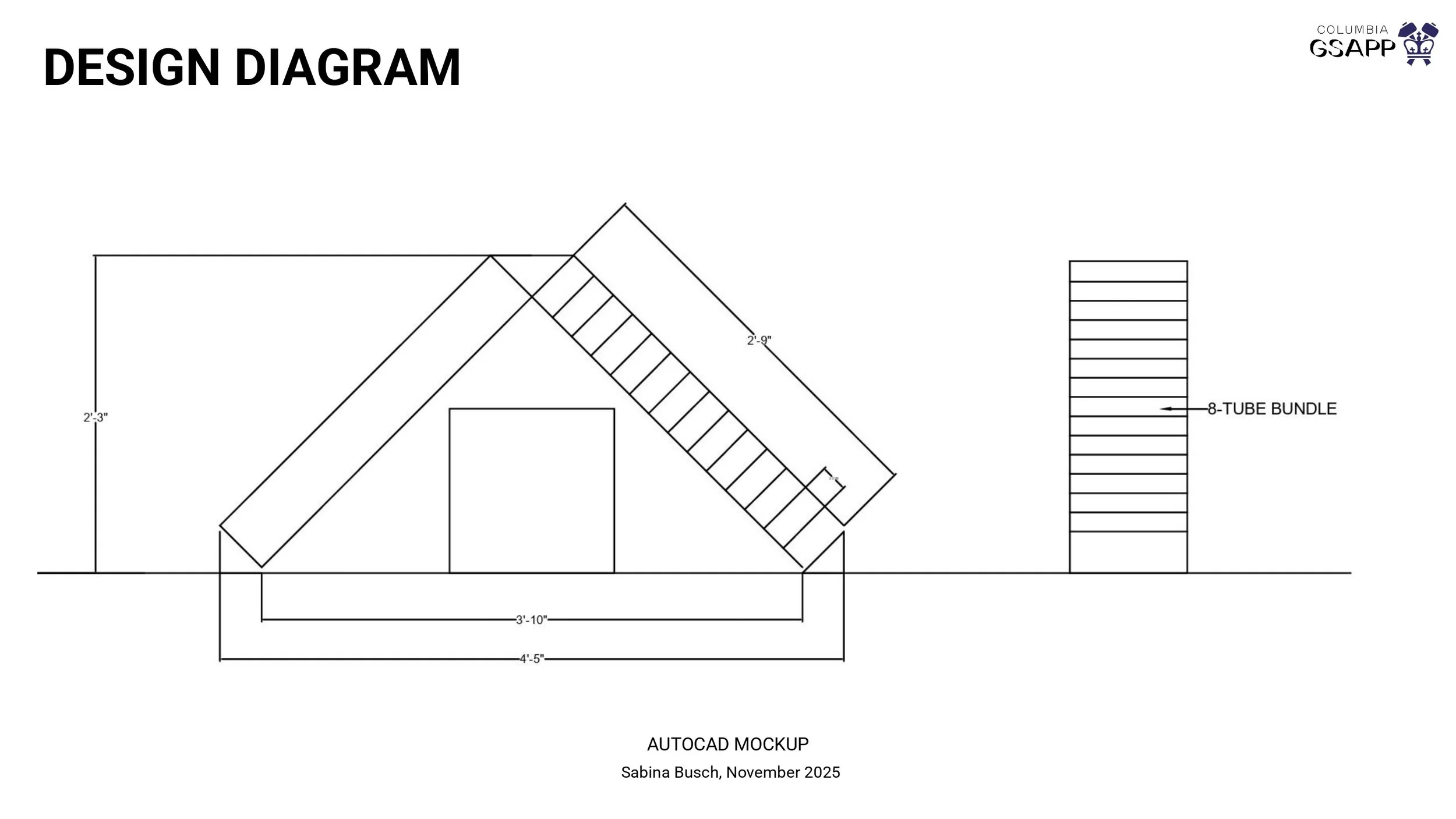

The arch consisted of 8-tube bundles assembled from standard cardboard mailing tubes using zipties, creating composite structural elements that combined light weight with surprising compressive strength. The tubes were cut to precise lengths and bundled together, with 80-grit sandpaper hot-glued to either side of the tube bundle. This allowed the arch to be disassembled for transport and quickly reassembled on-site without mortar, adhesives, or mechanical fasteners. Each tube bundle had a letter, which allowed for in-order sorting prior to the competition. The keystone, consisting of cardboard tubes cut into 45-degree angles, was filled with Quik-Rete, a fast-setting concrete. This added weight allowed compressive forces to operate on the cardboard bundles, keeping the arch legs stiff. The more weight added to the arch load, the stronger the legs became.mFollowing APT specifications, the built arch achieved a 36" minimum span with a maximum height of 28", depth of 10", and keystone depth of 4.5". The catenary-inspired curve was adapted to work with the tube bundle geometry, maintaining the principle of pure compression while accommodating the modular nature of the tube elements.

The bundles nested together through careful geometric planning, creating a self-supporting structure stabilized entirely by gravity and compression forces. At the 2025 APT Providence conference, teams assembled their arches under timed conditions before judges and APT attendees. The Columbia team's tube-bundle design demonstrated both the versatility of compression-only structures and the possibilities for innovative materials in traditional arch forms, coming in with a build time of 63 seconds, and holding a weight of 115 lbs during the competition. The Columbia team won ‘strongest arch.’

Competition Phase 3: Final Presentation

Beyond the timed arch-building competition, Phase 3 required teams to present their complete research and methodology to a panel of preservation professionals and APT conference attendees. The Columbia team delivered a comprehensive 10-minute presentation synthesizing their historic research, structural analysis, and preservation planning work, followed by responses to preservation challenge problems and a Q&A session with judges. Each team member introduced themselves and presented for at least one minute, demonstrating collaborative expertise across preservation, engineering, and architectural disciplines. The presentation covered the arch's transformation from gilded-age estate gateway to endangered neighborhood landmark, walked through the graphic statics methodology used to confirm structural stability, and outlined the critical preservation interventions needed to arrest ongoing deterioration. Video documentation of the Phase 2 Guastavino-inspired build and load testing provided visual evidence of the team's hands-on construction experience and understanding of compressive arch behavior.

Following the main presentation, teams addressed two preservation challenge questions selected earlier in the conference. These real-world scenarios tested the team's ability to apply their research insights to unfamiliar preservation contexts, connecting their specific work on the Seaman-Drake Arch to broader principles of masonry conservation, structural assessment, and intervention planning. Different team members responded to each question, demonstrating depth of knowledge across the full team. The team also designed aposter serving as a visual guide through the project which condensed the Phase 2 report into an accessible public-facing format, featuring the arch's compelling transformation narrative, annotated condition assessment drawings, graphic statics diagrams showing thrust line analysis, and documentation of the Guastavino tile construction process.

Both the poster and the final presentation are included below.